Recently, a customer from Turkey traveled thousands of miles to visit Fumart equipment production factory to see rotary die cutting machine. The Turkish customer, a supplier of medical supplies for medical stickers, visited our automatic die cutting machine finished product assembly workshop in Langfang and also visited the die cutting machine parts production plant.

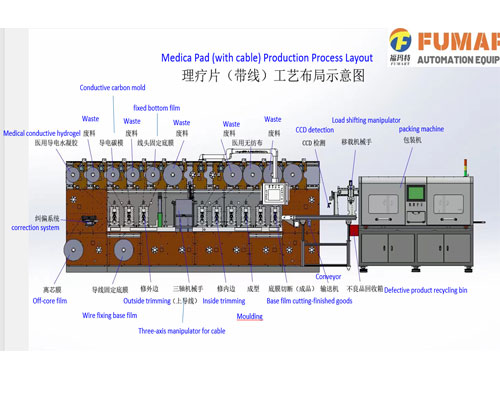

The customer detailed consultation of automatic die cutting machine, is Fumart research and development of automatic production equipment for medical stickers medical consumables, is a crossover application. The application not only changed the past machine production of a product limitations, but also greatly improved the efficiency of equipment, increased the rate of product production, from the past only producing two or three hundred pieces one minute, Up to now, the round knife machine produces 1,200 to 2,000 pieces per minute, and the good quality rate is more than 98%. In the past, it needed to manually add medicine cable, foam ring and detect, but now, from raw materials to finished products, detection and packaging are fully automatic in one machine, which truly realizes the medical patch machine, paste machine, band-aid machine and heart electrode machine. Plaster machine, indwelling needle paste machine, infusion paste machine, medical consumables production equipment, fully automated upgrade, it has to be said that this is a revolution of medical patch machine.

Functional Advantages

High efficiency and high energy, one machine multi- purpose, save money and labor; This medical physiotherapy patch machine videos

Band-aids, plaster stickers, infusion stickers, navel stickers, foot stickers, eye stickers and other kinds of paste can be used in a multi-purpose machine, circular pressing circular die cutting and laminating in one machine molding, one machine cost, do 90% of the paste products.

Less material alarm, cut off material stop, higher yield operation more worry independent servo control, more precise more efficient more stable automatic constant tension, more simple operation double system setting, one machine double out, one machine multi-purpose, more practical and stable multi group asynchronous, more save material full speed tracking, 60 meters asynchronous tracking without deviation maximum speed 60 meters/min double eye tracking asynchronous matching, According to their positions, accurate alignment, die cutting, transfer, drip, button, detection, packaging and other fully automated assembly line connection, more intelligent and less labor, more details, click here

Manager Wang from the Foreign Trade Department, Manager CAI from the Technology Department and Manager Han from the Production Department accompanied the customer to visit the Format finished product production factory and parts production factory. This is the first foreign customer visit since the outbreak was lifted.

During this visit, the customer not only had a detailed understanding of the operation of the automatic die cutting machine, consulted the detailed parameters of the equipment, but also personally measured the area of the equipment.

During the visit, the customer consulted many questions about the operation and function of the equipment in detail, consulted the detailed parameters of the equipment, and personally measured the area of the equipment, etc. Mr. CAI, manager of the technology department of Fumart, demonstrated and explained the operation one by one on the site.

You are also welcome to visit Fumart or make samples on site. If you are not convenient to visit, you can send samples to us for test. We can talk about cooperation after the samples pass the test.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat