Fumart provide One-Stop service, from Supply Chain, Production, Storage, Packaging, QC, Pre-shipment Inspection, to After-sales Service

Supply Chain

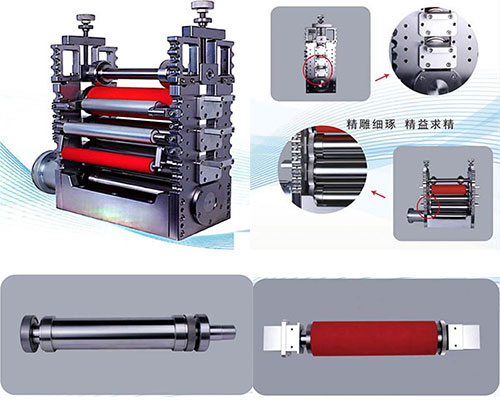

1. Equipment key parts list---tool holder, roller, motor, electrical controller system, etc.

2. Mechanical parts are made by our own factory, which ensures the low cost & good quality, has huge advantages in the combination with the equipment.

3. Electrical components adopt high-end brands such as Omron, can also be customized according to customer requirements.

4. Fumart equipment is fast, stable, high precision and reliability, usage times long; others issues happens maybe after 1.5 years.

Production Process

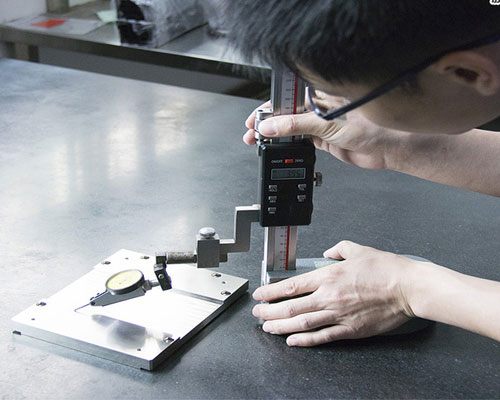

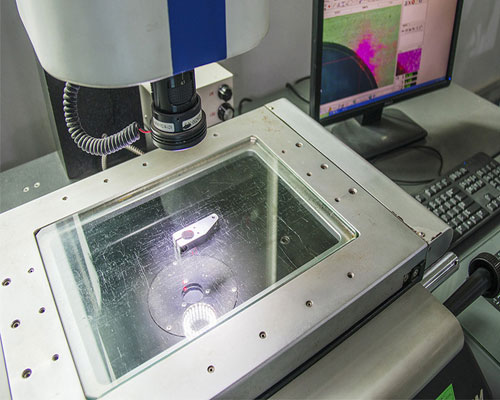

1. IQC is the first level to control the equipment quality before production, which affects not only the final products quality, but also the various indirect costs.

Raw material surface IQC

Raw material height IQC

Raw material size IQC

Raw material harness IQC

Raw material density IQC

2. During the equipment assembly process, scientific division of assembly units is carried out, and operation is carried out according to the approved process technology. Refining the standard to each small unit can not only improve the assembly efficiency, shorten the waiting blank period of customers, but also allow quality control to enter each assembly unit for pre-intervention to ensure product quality

Control screen assemble

RollerRoller assemble

RollerRoller tolerance test

Tool assemble and test

Electrical assembly

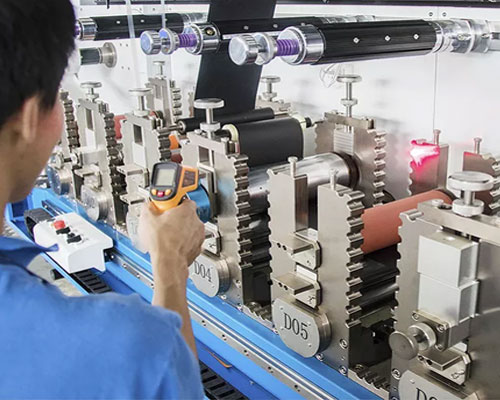

3. After the completion of assembly, do the whole machine trial run test.

Appearance inspection, whether the mechanical structure is coordinated operation, the performance of the electrical components is excellent, and the parameters of the operation are up to the standard, the noise level of the operation process, the sample precise testing, etc.

Equipment outlook QC

Running temperature QC

Running with sample test

Sample QC

Sample precise QC

Storage system

All the data of stock, entering/out-of- warehouse, in transit, are recorded in ERP system;

Physical count in the material and FG warehouse per month, update the inventory aging report to the accordingly department, to help to handle of sluggish materials.

Packaging System

Equipment Inner Package: Vacuum PET film .

Equipment and spare parts all in one 40ft container , By sea

QC System

Professional inspection expert

QC Equipment: all kinds of QC equipment used in all production process.

QC Standard: Product Certificates : CE & Factory Certificates : ISO9001

Pre-shipment Inspection System

Before shipment, Customer or our own quality colleagues do the final check, the strict quality inspection management system to ensure zero errored.

After-sales Service System

Engineers be dispatch to customers place for training and debugging

One year free warranty (except consumables), life paid maintenance and overseas service

Appointed account manager to help solve any problems at any time.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat