RFID PROCESSING SOLUTIONS

RFID Industries:

RFID components.

Access management.

Tracking of goods.

Tracking of persons and animals.

Toll collection and contactless payment.

Machine readable travel documents (E-passport).

Machine description

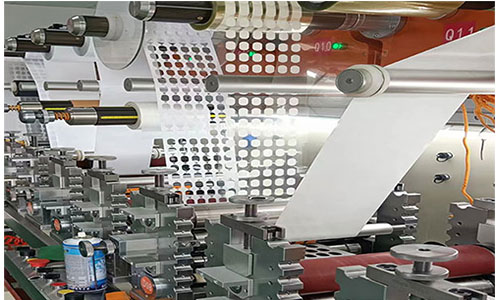

RFID (radio frequency identification technology) label high-speed composite automatic rotary die cutting machine, (referred to as: RFID composite machine) commonly known as RFID laminating machine, RFID machine, electronic label composite machine.

The composite machine is to bond two or more layers of material with adhesive to become one, so that the original material gets new functions. Such as film and aluminum foil, film, paper, non-woven fabrics are often used. RFID tags are mainly used in retail, clothing, electronics, medical and health, logistics and other industries of all kinds of tickets, clothing tags and other products of composite rotary die cutting process.

The working principle of the RFID label compounding machine is to bind the antenna and inlay by the bonding machine, and then the blank label and inlay are bonded by the die-cutting station for composite die-cutting. If it is necessary to make it into a self-adhesive type, it is necessary to add adhesive and backing paper. If it is made into an ordinary tag, the data processing of the tag can be directly carried out (the RFID tag coding inkjet detector can be used to add data), and the finished RFID tag can be directly applied in the terminal.

Machine features

ALL cutter holder's movements are controlled by JAPAN Omron servomotor with enough torsion ,stable acceleration and deceleration, precision can be ±0.05--±0.1.

All unwind & rewind shafts are driven separately by servo motors. The unwinding, rewinding, straight & reverse rotation are more flexible and controlled by high sensitivity tension sensor shaft's feedback to ensure smooth running.

It can save more 200 kinds of SOP data, improve standard level, and reduce dependence on Operator's experience and reduce more than 60% material waste

Main unwind EPC system can stabilize the material feeding into blade holder

Movable auxiliary unwind shaft

Fracturing detecting machine stop or alarming to reduce material waste.

Machine has the function of asynchronous laminating which can save material.

Color code electric eye tracking system can meet the demand of position precision of produce printing product.

The main operation interface adopts touch panel, with picture display for easy operation. Keyboard, mouse and hand touch are all available.

CCD testing system can test position precision all the time during the whole process and then feedback to PLC which send orders to servo motors to adjust position.

Machine advantages

Great for high-volume orders because of the machine’s cutting speed

Offers an exceptional level of precision that exceed flatbed machines, making it the better choice for materials that are difficult to manipulate

Can perform multiple functions at once, including printing, perforating and laminating Allows kiss cutting, which cuts through the main material but leaves the backing paper intact, cost down

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat