Automobile Processing Solutions

Die Cutting Laser Converting is through the machine to process materials into different shapes and sizes, so as to meet the different needs of the industry, the car has complex parts and decoration, often need a lot of professional auxiliary materials.

Automobile Industries:

|

|

Applications:

Automobile dial panel parts, gaskets for carriages, sponge materials, explosion-proof membranes, shockproof pads, vehicle touch screen navigation equipment, copper foil, aluminum foil and brake parts, battery modules, nameplates & Badging, etc.

Materials of double-sided tape, foam tape, transfer tape, anti-plasticizer double-stabilized tape, fog reduceable tape, can be used in auto parts after segmentation, die cutting processing. such as: instrument panel, lamp shell, decoration, etc., the actual installation is faster, simpler and more accurate.

1. Damping aluminum foil tape die-cutting products, electrical tape die-cutting products, foam tape sealing products.

KL- Large die-cutting machine.

2. Cutting die of rearview mirror mirror seat tape

3. Kiss-cutting is a special part of sound-absorbing materials

4. Automotive monitoring LCD, VCD, DVD die-cutting products for auto parts conveyor belt die-cutting products, a variety of interior parts tape die-cutting products.

5, protective pressure cushion materials, such as die-cutting products, roof structure, sealing tape and other materials.

Noise reduction and shock absorption: between metal parts and plastic parts, between plastic parts and plastic parts, between metal parts and metal parts, paste die-cutting products made of foam, blankets, anti-scratch textiles, etc., to play a role in noise reduction and shock absorption.

Interior and buffer: All kinds of neoprene rubber, foam and silicone materials, after precision die-cutting, used in decorative parts, doors and ceilings. Other applications: car logo installation, high temperature resistant spray masking paper, airbag sealing, speaker cover, temporary protection, etc.

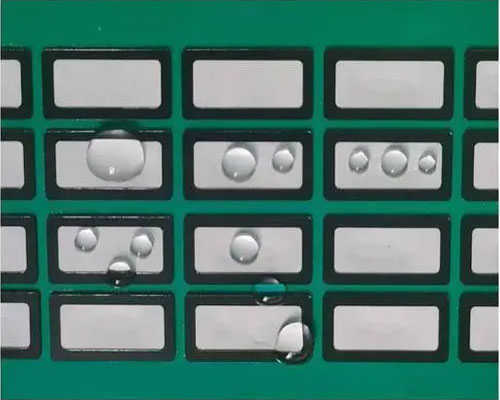

Rotary cutting dies processing products: circuit board fixed double-sided adhesive process design Die-cutting structure: from the top down: the first layer is the release film, the second layer is one side of the black and white side of the white glue, black and white two double-sided adhesive closely connected, leaving a gap of 0.1mm, the third layer is a white PET release film material belt, with reading holes.

Die cutting systems processing product requirements: ensure cleanliness, product no deformation, no overstock, no overflow and other bad phenomena.

Foam die cutting machinery processing:

1. Overlap the two layers of double-sided tape on the circular knife machine, put the black double-sided tape on the white double-sided tape, the double-sided tape comes with the release paper is not removed;

2. Use the first mold, that is, the slitter knife, to slitter the black hole and a small frame directly from the black and white, and die cut the black hole and a small frame.

3. Remove the waste material between the overlap of the double-sided tape, and then remove the release paper of the double-sided tape, and then compound the 75g transparent release film;

4. Die cutting the whole outer frame and inner frame. The suction box is used to wash the inner frame waste, the machine is discharged the outer frame waste, and the coil is collected;

5. Manually check whether the product has spilled glue, dropped pieces, poor size, packaging and shipping.

Key points of thermal die cutting machinery processing technology: Considering the properties of self-adhesive label materials, such as the strength of self-adhesive surface materials, the characteristics of adhesives and the strength of the backing paper have a certain impact on the die-cutting quality of the label, there should be certain requirements in the selection of self-adhesive materials and label processing, and the use of high-quality materials or corresponding die-cutting processes to improve the die-cutting quality of the label. Through many years of practice, Fumart summarized the problems encountered in the work, and put forward the correct selection of self-adhesive materials, effectively improve the quality of die cutting several matters for attention.

(1) Not use die-cutting plate die-cutting film materials that have been die-cut paper materials, because the blade has been worn and is not suitable for re-die-cutting film.

(2) When pressing flat die cutting, try to reduce the die cutting area, especially the full plate of small labels, because the layout is large, the row of knives is more difficult to ensure the quality.

(3) The pad should be replaced often when the flat die-cutting is pressed, especially when the processing is long, because the cut mark will affect the die-cutting quality of the new format label.

(4) Often check the quality of die cutting, especially the automatic labeling label. To avoid mass quality problems. The specific inspection method is to apply the signal pen on the backing paper to check the penetration of the cut marks on the backing paper.

(5) Die-cutting large-area, complex pattern labels, to professional manufacturers to make die-cutting plate, so as to ensure the precision of die-cutting.

(6) To maintain the sharpening of the blade, establish a file to record the use of each die-cutting plate in order to replace the blade in time.

(7) Use a special blade with a small Angle and high hardness to die cut film self-adhesive materials, especially PET materials.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat