I. Overview

Round knife machine is a die cutting machine, called "multi-station rotary die cutting machine", referred to as multi-station rotary, commonly known as round knife die cutting machine, hob machine or multi-station hob machine.

Round knife die cutting machine from a simple three stations to five stations, seven stations to the present 32 stations, more and more auxiliary shaft, equipment use is more and more flexible. Rotary die cutting machine adopts servomotor drive, tension control, control precision is relatively high.

2, the working principle of round knife die cutting machine

Round knife machine is a die cutting machine, called "multi-station rotary die cutting machine", referred to as multi-station rotary, commonly known as round knife die cutting machine, hob machine or multi-station hob machine. It in the form of hob continuous rotation die cutting processing, die cutting machine is one of the highest production efficiency of the machine. Divided into 2 seats, 3 seats, 5 seats, 7 seats and other series of round knife die cutting models. Round knife die cutting is through the blade and roller extrusion material to achieve the purpose of die cutting, roller is a smooth surface and hard cylindrical shaft, round knife processing is in a process to complete the composite and processing of multi-layer material die cutting method.

At present, from the point of view of the tension control system of the multi-station round knife die cutting machine, it is generally the use of automatic tension control program, through the pre-set program, automatic calculation of retracting and discharging shaft diameter, timely calculation of torque, so as to ensure the stability of tension. Automatic program tension control system is widely used in Europe and America. In the view of many operators, the program automatic tension control system advantages are very obvious, such as the material does not need to be wound many times; Reduce material scratch, deformation; Easy to operate, easy to upgrade procedures. This is the basic working principle of the round knife die cutting machine.

3, FUMART round knife die cutting machine partial function

Multi - station round knife die - cutting machine is high efficiency, high precision processing equipment. Equipment is widely used in mobile phones, digital cameras, computers and other electronic adhesive accessories die cutting. It has the advantages of multi-layer composite, multi-die cutting, waste discharge, multi-group winding and discharging simultaneously, advanced technology, reasonable process, compact structure, flexible and convenient operation, and high production efficiency. Strong ability to adapt to the process of different products, die cutting quality and production efficiency is far higher than other die cutting, die cutting products to improve production capacity, reduce the production cost of the ideal choice. In order to adapt to different specifications of die cutting products, according to the requirements of die cutting manufacturers tailored die cutting equipment.

(1) Two-speed function: one device can be used as two devices. Each tool holder can realize system switching, any combination of each tool holder, flexible setting, independent counting, start-stop control, do not affect each other.

(2) Asynchronous function: it can realize small piece paste large piece, reduce cost and increase efficiency. Normal tool die through asynchronous virtual setting of a tool shaft (sliding material), to make small pieces of composite to large products, that is to save the cost of the tool die, but also save the cost of materials.

(3) The function of cutting (sticking) irregular sheet (graphite sheet) : you can cut irregular sheets into regular, unequal spacing sheets, you can also arrange unequal spacing sheets into equal spacing sheets, and then accurately compound equal spacing sheets into products. Suitable for special materials and complex technology.

(4) Multiple groups of asynchronous parameter setting, you can set one to four groups of different jump distance, powerful, flexible setting.

(5) Automatic tracking and adjustment function: can realize automatic adjustment of sleeve cutting size or post-press die cutting, in accordance with the set size alignment, set accurate, high degree of automation, labor saving.

(6) Independent servo control: can realize separate start and stop, positive and negative rotation, proportional/synchronous. Set the follow speed arbitrarily.

(7) Automatic constant tension control, automatic cutting protection, torque changes with the size of the diameter, to maintain constant tension.

(8) Automatic correction function: it can realize automatic correction of main materials.

(9) With safety protection function, the maximum protection of personal safety. High safety factor, simple and convenient operation.

(10) In addition to electrostatic function: eliminate static electricity and dirt material, improve the quality of die cutting.

4. Performance parameters of FUMART multi-station round knife die cutting machine

Brand: FUMART

Performance category: Rotary die cutting machine

Origin: FUMART Automation Equipment Technology Co., Ltd.

Applicable material form: roll form

Products: Multi-specification, multi-material and multi-occasion

Die cutting speed: 60 m/min

Rated power: 40kw

Rated voltage: 380v

Accuracy: ±0.05mm

Panel: touch screen

Automatic tag: Yes

Constant tension: Yes

Multi-group asynchronous: Yes

Asynchronous fit: Yes

Asynchronous tracing: Yes

Broken material alarm: Yes

Flexibility: Each rewinding and unwinding roller is independently servo controlled, which can change the direction flexibly

Extensibility: It can change the tool, add the tool and process the bit at any time

Station, size: custom

Effective die cutting width: custom

Technical services: one-to-one support from local professionals

5. FUMART multi-station round knife die cutting machine application field

1), mobile phone equipment (mainly used for double-sided adhesive die cutting machine, all kinds of protective film die cutting machine)

Mobile phone is the most widely used die cutting products in the field. The operation of mobile phone is increasingly intelligent, the fuselage is thinner and thinner, are inseparable from the continuous innovation of die cutting technology and the support of ultra-fine processing technology, especially the double-sided adhesive die cutting parts of electronic products.

Take a look at the parts that need to use die cutting process in the mobile phone field:

Protective film, touch screen, display screen, backlight film, Windows, black and white adhesive, lens protection, nameplate, sequence label, earphone/microphone O-ring fixed, earphone/microphone dust screen, window/microphone dust pad, handset/microphone cushion, handset/microphone dust pad, PCB fixed plate, LCD reflection film, backlight, battery compartment, battery label.

2), tablet equipment (mainly used for double-sided adhesive die cutting machine, all kinds of protective film die cutting machine)

Tablet are the device segment most closely associated with the die cutting industry after mobile phones. The trend of tablet computers replacing notebooks is inevitable, and the more humanized and intelligent tablet devices are also closely related to the die cutting process. So, what are the parts of the die cutting process used in the tablet device? As follows:

Protective film, touch screen, display screen, touch screen washer, touch screen fixed rubber pad, display screen fixed rubber pad, camera lens, motherboard, port insulation protective layer, top cover, label, microphone dust screen, LED board, FPCB fixed, battery bin fixed, battery bin cushion, window fixed, microphone dust screen, microphone cushion, microphone dust screen, button switch, back light source .

3), smart watch equipment (mainly used for double-sided adhesive die cutting machine, all kinds of protective film die cutting machine)

Recently, more hot smartwatch products are still a wide range of die cutting products, smart watch again and again shine in the world behind, also cannot leave the die-cutting more sophisticated, high precision technology support.

Smartwatch applied to die cutting components: watchband, screen protection film, touch screen, display screen, circuit motherboard, backlight components, air filter, battery interface and other soft board components.

4), digital products (mainly used for double-sided adhesive die cutting machine, all kinds of protective film die cutting machine)

All kinds of digital products are filled with our world, and die cutting technology is also ubiquitous in life and work.

Camera, camcorder, digital camera, digital speaker equipment (such as opera machine, etc.), MP3, MP4, MP5, recorder, scanner, DVD player, storage card, telephone, set-top box, satellite receiving device, TV, and CNC household appliances production and processing are to use die cutting equipment.

Take digital cameras for example:

Rubber pad, PCB protection, flash memory card, LCD cushion fixed, button and hard material fixed, mirror cover fixed, flash battery/cushion fixed, reflective mold fixed, panel fixed, LCD module fixed, nameplate, FPCB, LCD module fixed, FPCB fixed, FPCB fixed, panel fixed, serial number label, Receiver/microphone dust cushion, lens cushion, FPCB fixed

5), LCD equipment

The invention and popularization of LED and LCD display devices have made our world more colorful and visually richer. Similarly, continuous innovation in this field is also inseparable from the support of die-cutting equipment.

It is used in liquid crystal optical films, polarizers, backlights, various rubber pads, reflectors, diffusers, and light-shielding tapes at the components of rear projection lamps, for dust-free microfabrication in clean rooms.

6), printing industry (mainly used in self-adhesive die cutting machine, all kinds of paper cutting machine)

Office supplies: copy paper, release paper, filling paper, notes, notebooks, bills, requisition, leave, invoices, statements and other paper supplies.

Commercial super paper: labels, price stickers, shopping receipts, commodity name stickers, promotional stickers, etc.

Industrial paper: Paper or board, such as kraft paper board, corrugated core paper, coated white paper board, grey board, etc., used to make cartons, boxes, cups, plates, etc

7), medical industry (mainly used in medical sticking machine, double-sided adhesive die cutting machine)

A variety of digital touch screen equipment in the medical field, such as: blood glucose meter, microscope, CT scan, electroencephalogram machine, electromyography machine, etc.

Medical supplies: hemostatic stickers, medical masks, antipyretic stickers, capsule boards, packaging boxes, western medicine paper bags, syringe bags, gauze and other dressing supplies.

Maternal and infant products: such as diapers, sanitary pads, lactation pads, urine pads, saliva towels, etc.

8), Adhesive field

AB adhesive, 3M, TESA, black and white adhesive, self-adhesive, double-sided adhesive, easy to tear adhesive, conductive cloth, PE foam adhesive, PET film, PVC film, electrostatic film, blue film, insulating materials (PVC sheet, PET sheet, fast bus paper, green shell paper, high temperature resistant insulating adhesive)

9), Clothing

Velcro, tag, trademark, zipper, chest pad, collar pad, shoulder pad, elastic, rubber band and other clothing accessories processing.

10), The beauty industry

Various facial masks, eye stickers, nose stickers, foot stickers, weight loss stickers and so on.

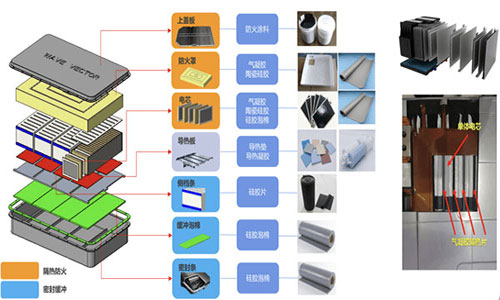

11), New energy

Batteries, solar energy

It is used for stamping of lithium battery pole piece, collection line, ccs, flexible circuit board, battery insulation sheet, highland barley paper, chassis, lithium battery general insulation pad, solar pole piece, sun protection film, etc., to insulate and buffer them effect.

12), Automobile

Automobile dial panel parts, gaskets for carriages, sponge materials, explosion-proof membranes, shockproof pads, vehicle touch screen navigation equipment, copper foil, aluminum foil and brake parts, etc.

6. Precautions for FUMART multi-station round knife die Cutting Machine

1). Do not knock the edge when adjusting the gap of the edge to prevent the edge from cracking. Generally, adjust the lower tool position before adjusting the blade clearance. During the adjustment, loosen the fastening bolts on the blade base using a professional tool, move the blade base to the proper position, and then tighten the fastening bolts.

2). the operator must be familiar with the general structure and performance of the equipment, it is strictly prohibited to use the equipment beyond the performance. The mold on the operating platform has been positioned after accurate adjustment by the manufacturer, and shall not be adjusted unless special circumstances.

3). Adjust the upper tool in the same way as the lower tool. Adjust the upper tool to an appropriate gap according to the thickness of the cutting plate, and align the upper and lower press wheel with the tool. Adjust the position of each tool in turn.

4). Clean the workbench and its surrounding tools and items unrelated to work before starting. Switch on the main power supply, then close the speed control box switch, adjust the rolling speed. The procedure is reversed when the machine is shut down.

7, Rround knife die cutting machine maintenance method

1). die cutting carton will produce a lot of waste paper edge, paper wool, a little attention will enter the chain transmission parts, die cutting part of the moving platform and some rotating motion parts, and may block the photoelectric detection, causing failure. Therefore, be sure to clean the body of the round knife die cutting machine.

2). operate in strict accordance with the operating procedures, the blade must always keep clean, unpainted part of the anti-rust grease.

3). Check and repair the switch, safety and handle regularly to ensure its reliability.

4). It is strictly prohibited for non-designated personnel to operate the equipment, and it must be stopped when people leave the plane.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat