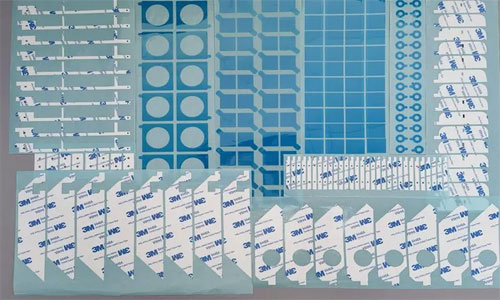

In the electronics industry, laser rotary die cutting machines are commonly used for various applications such as cutting and shaping flexible printed circuit boards (PCBs), membrane switches, gaskets, insulators, and other electronic components.

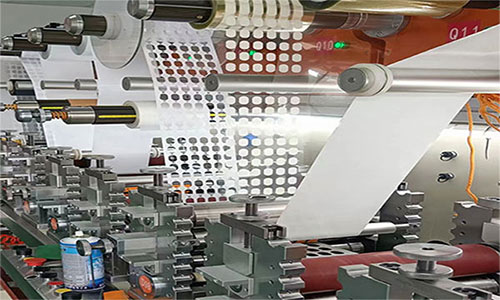

Here's how a laser rotary die cutting machine works in the electronics industry:

1. Design and Programming: The desired shape or pattern for the electronic component is designed using CAD software. The cutting path and parameters are then programmed into the machine's control system.

2. Material Preparation: The material, such as a flexible PCB or membrane switch sheet, is prepared and loaded onto the machine. The material may be in the form of rolls or sheets, depending on the specific application.

3. Cutting: The laser rotary die cutting machine uses a high-powered laser beam that is directed by mirrors and lenses to follow the programmed cutting path. The laser beam rapidly cuts through the material, creating precise and clean cuts.

4. Material Handling: As the material is cut, the waste or excess material is automatically removed from the cutting area. This can be done through suction or other mechanisms to ensure a clean and efficient cutting process.

5. Inspection and Quality Control: After the cutting process, the finished electronic components are inspected for accuracy and quality. Any defects or errors can be identified and corrected, ensuring that only high-quality components are produced.

6. Post-Processing: Depending on the specific application, the finished electronic components may undergo further processing such as printing, folding, assembly, or packaging.

The use of laser rotary die cutting machines in the electronics industry offers several advantages:

1. Precision: Laser cutting provides high accuracy and precision, ensuring that intricate and complex shapes are cut with minimal distortion or damage to the electronic components.

2. Speed: Laser cutting is a fast process, allowing for high production rates and increased efficiency in the electronics manufacturing process.

3. Minimal Heat or Mechanical Stress: Laser cutting generates minimal heat and mechanical stress, making it suitable for delicate and sensitive electronic materials.

4. Flexibility: Laser cutting machines can work with a wide range of electronic materials, including flexible PCBs and thin films.

5. Cost-effective: Laser cutting eliminates the need for expensive tooling or dies, reducing setup costs and enabling faster production turnaround times.

Overall, laser rotary die cutting machines play a crucial role in the electronics industry by providing precise, efficient, and cost-effective cutting solutions for various electronic components and materials.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat