rotary die cutting machines are widely used in the production of gaskets due to their ability to accurately cut various gasket materials with high precision and efficiency. Here are the technical specifications and features of rotary die cutting machines that make them suitable for gasket production:

1. Cutting Accuracy: Rotary die cutting machines are designed to deliver precise cuts in gasket materials. The use of high-precision rotary dies ensures accuracy and repeatability in cutting different shapes and sizes of gaskets.

2. Material Compatibility: Rotary die cutting machines can work with a wide range of gasket materials, including foam, rubber, cork, felt, and non-asbestos materials. The machines are capable of handling both soft and rigid materials with consistent results.

3. Speed and Efficiency: These machines are designed to operate at high speeds, allowing for fast production rates in gasket manufacturing. The high-speed rotary die cutting process ensures efficient cutting of large volumes of gasket material.

4. Material Handling: Rotary die cutting machines have mechanisms for handling and feeding gasket materials. They can handle rolls or sheets of gasket material and ensure smooth and precise material feeding during the cutting process.

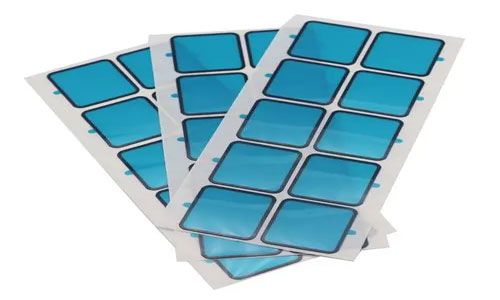

5. Die Options: Rotary die cutting machines offer a variety of die options to accommodate different gasket designs and production requirements. The dies can be customized to create specific shapes and patterns required for gaskets, such as round, rectangular, or irregular shapes.

6. Waste Removal: As the gasket material is cut, the waste or excess material is automatically removed from the cutting area. Rotary die cutting machines have waste removal mechanisms, such as suction systems or vacuum tables, to maintain a clean cutting environment and improve efficiency.

7. Inspection and Quality Control: Some rotary die cutting machines incorporate inspection systems to check the quality and accuracy of the cut gasket components. These systems can detect defects or inconsistencies and reject or mark the faulty components for further inspection or correction.

8. Software Control: Rotary die cutting machines are typically controlled by software that allows for easy programming and adjustment of cutting parameters. This software enables operators to create, modify, and store cutting patterns, optimizing the cutting process for different gasket designs.

9. Versatility: Rotary die cutting machines can be used for a wide range of gasket applications, including automotive, industrial, electrical, and medical industries. The machines offer versatility in terms of material compatibility and cutting capabilities, allowing for the production of various types of gaskets.

Overall, rotary die cutting machines provide precise, efficient, and versatile cutting solutions for gasket production. They can handle different gasket materials, deliver high-speed production, and enable quality control through inspection systems and software control.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat