Mode: FMT250-32B

Stations: 32 Stations / 64 Spindles

Web Width range: 150/250/350/550/650mm

Max press speed: 60m/min

Cutting precision: ±0.1mm

Material form: Roll

Gearing pitch: 1/8''

Electrical: AC400V 50HZ 106KW

Dimension: 11200*1420*2350mm

Weight: 15T

Certification: CE & ISO

FMT250-32B Automatic High Efficiency rotary die cutting machine Screen Frame Adhesive Printer for Protective Film Tape OCA rewinding Compound Machinery Supplier with CE

Fumart high efficiency rotary die cutting machine plays a vital role in the production of cellphone back adhesive tapes or touch screen protective films. This machine enables manufacturers to quickly and accurately cut the raw materials into the desired shapes and sizes, thereby improving production efficiency. Its user-friendly operation allows for automated processes, reducing manual labor and lowering labor costs. Additionally, the rotary die cutting machine ensures precise cutting with minimal errors and consistent cutting quality. Its versatility extends beyond the production of cellphone back adhesive tapes and touch screen protective films, finding applications in manufacturing protective components and precision parts for other electronic products.

Characteristic:

· Module design: One machine, by changing tools or adding apparatus (below details), can cover most of the industries, such as Medical and Cosmetic, Anti Dust Foams Meshes, Conductive Insulation Pads, Graphite Thermal Pads, Screen Frame Adhesives, UHFHF RFID Tags Labels, etc.

· ALL cutter holder's movements are controlled by JAPAN Omron servomotor with enough torsion, stable acceleration and deceleration, precision can be ±0.05--±0.1.

· All unwind & rewind shafts are driven separately by servo motors. The unwinding, rewinding, straight & reverse rotation are more flexible and controlled by high sensitivity tension sensor shaft's feedback to ensure smooth running.

· It can save more 200 kinds of SOP data, improve standard level, and reduce dependence on Operator's experience and reduce more than 60% material waste

· Main unwind EPC system can stabilize the material feeding into blade holder

· Movable auxiliary unwind shaft

· Fracturing detecting machine stop or alarming to reduce material waste.

· Machine has the function of asynchronous laminating which can save material.

· Color code electric eye tracking system can meet the demand of position precision of produce printing product.

· The main operation interface adopts touch panel, with picture display for easy operation. Keyboard, mouse and hand touch are all available.

· CCD testing system can test position precision all the time during the whole process and then feedback to PLC which send orders to servo motors to adjust position.

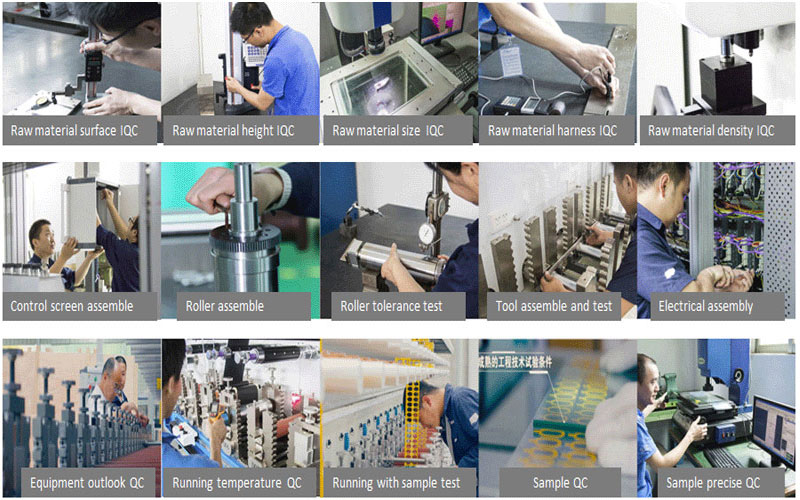

Production and QC Process:

After-service:

§ Engineers be dispatch to customers place for training and debugging

§ One-year free warranty (except consumables), life paid maintenance and overseas service

Advantages:

The advantages of using a rotary die-cutting machine in the production of cellphone back adhesive tapes or touch screen protective films are as follows:

1. High precision and accuracy: Rotary die-cutting machines are designed to provide precise and consistent cutting of materials. This ensures that the cellphone back adhesive tapes or touch screen protective films are cut to the exact shape and size required, reducing wastage and improving the overall quality of the products.

2. High-speed production: These machines are capable of cutting materials at high speeds, allowing manufacturers to produce a large quantity of cellphone back adhesive tapes or touch screen protective films in a shorter period of time. This increases production efficiency and helps meet tight deadlines.

3. Cost-effective: By automating the cutting process, rotary die-cutting machines reduce the need for manual labor. This not only lowers labor costs but also improves the overall production capacity of the manufacturing line. Additionally, the accurate cutting ensures minimum material wastage, further contributing to cost savings.

4. Versatility: Rotary die-cutting machines are highly versatile and can be used for cutting a wide range of materials, including various types of adhesive tapes, protective films, and other thin materials used in electronic products. This versatility allows manufacturers to adapt to different product requirements and diversify their product offerings.

5. User-friendly operation: These machines are designed with user-friendly interfaces and controls, making it easy for operators to set up and operate the machine. This reduces the need for extensive training and minimizes the chances of human errors during the production process.

6. Consistent cutting quality: Rotary die-cutting machines ensure consistent cutting quality, with minimal variations or errors in each piece. This results in a uniform and professional finish of the cellphone back adhesive tapes or touch screen protective films, enhancing the overall aesthetic appeal and functionality of the final product.

Applications:

1. Flexible Printed Circuit (FPC): It can cut and shape FPCs into desired shapes and sizes for use in various electronic devices.

2. Labels and Stickers: The machine can die-cut labels and stickers from different types of materials, such as paper, plastic, and vinyl.

3. Gaskets and Seals: It can cut gaskets and seals from materials like rubber, foam, or silicone, which are used in automotive, industrial, and other applications.

4. Packaging Materials: The machine can cut and shape packaging materials, such as cardboard, corrugated board, and foam, for making boxes, inserts, and protective packaging.

5. Membrane Switches: It can cut and shape membrane switches, which are used in control panels, keyboards, and other electronic devices.

6. Insulation Materials: The machine can cut insulation materials, such as fiberglass, Mylar, or Nomex, for use in electrical equipment or HVAC systems.

7. Automotive Interior Parts: It can cut and shape materials like leather, fabric, or foam to produce automotive interior parts like seat covers, headrests, and armrests.

8. Medical Components: The machine can cut medical components, such as medical-grade tapes, filters, or foam pads, used in medical devices and equipment.

9. Industrial Components: It can cut and shape various industrial components, such as gaskets, pads, spacers, or washers, made from materials like rubber, foam, or PTFE.

Cases

Packaging

1. Inner Package: Vacuum PET film

2. In Containers, By sea

FAQS:

Q1:Why use a rotary die cutting machine to produce smartphone back protection tape or touch screen protectors?

A:The rotary die cutting machine offers high precision and high-speed production, ensuring that the smartphone back protection tape or touch screen protectors are precisely and consistently cut. This improves product quality and reduces waste. Additionally, the rotary die cutting machine increases production efficiency and reduces labor and costs.

Q2:What materials are suitable for the rotary die cutting machine?

A:The rotary die cutting machine is suitable for various thin materials, such as various tapes, protective films, and other thin materials used in electronic products. Its versatility enables manufacturers to meet different product requirements and diversify product supply. Q3:How does the rotary die cutting machine ensure cutting quality?

A:The rotary die cutting machine provides consistent cutting quality, minimizing variations and errors with each product. This ensures the consistency of the appearance and functionality of the smartphone back protection tape or touch screen protectors, enhancing the aesthetics and usability of the final product.

Q4:What convenience does the rotary die cutting machine offer in operation?

A:The rotary die cutting machine has a user-friendly interface and controls, allowing operators to easily set up and operate the machine. This reduces the need for extensive training and minimizes the chances of human errors during the production process. Q5:Is it cost effective to use a rotary die cutting machine to produce smartphone back protection tapes or touch screen protectors? A:The rotary die cutting machine reduces the need for manual labor and lowers labor costs through automated cutting processes. It also improves the overall production capacity of the production line. Additionally, the precise cutting ensures minimal material waste, further cost savings.

Fumart Factory:

Fumart Automation Equipment Technology is a professional manufacturer of rotary die-cutting machines and die-cutting machine accessories. We have advanced production facilities and a technical team dedicated to providing customers with high-quality products and excellent services.

Our rotary die-cutting machines adopt the latest cutting technology and high-precision tools, enabling precise cutting of various materials such as paper, tapes, films, and plastics. They have stable performance and high production efficiency, and can meet the needs of different industries.

At the same time, we also provide various die-cutting machine accessories, including cutting dies, anvil cylinders, rotary tooling, spindle, blades and pressure pads. These accessories are precision processed and have excellent wear resistance and durability, effectively prolonging the service life of the machine and improving production efficiency.

Our products are widely used in packaging, printing, leather, furniture, and other industries, and are highly praised by customers. We not only provide reliable products but also customized solutions and technical support to meet different production needs.

Whether you are an individual user or a large company, we can provide you with the most suitable products and services. Please feel free to contact us for more information about our company and products. We look forward to cooperating with you!

OUR EXHIBITIONS:

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat