Mode: FMT250-10B

Stations: 10 Stations / 20 Spindles

Width range: 150/250/350/550/650mm

Max speed: 70m/min

Cutting precision: ±0.1mm

Dimension: 4600*1420*2350mm

Weight: 4.5T

Certification CE & ISO

Quick-change modular various design

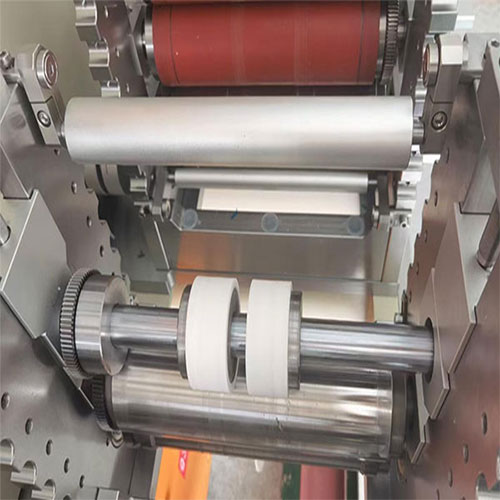

FMT250-10B Label Making Machine

Advanced processing technologies.

Fast, Stable and Multitude Capability, with extremely High Precision and Reliability.

Fumart is a leading manufacture of industrial die cutting equipment manufacturing technologies and solutions, we also provide Equipment Rental and Outsourcing Services, for those factories whose temporary peaks in production need fulfilling and uncertainty about machine investment for in-house operation.

1. Technological process

Slitting --- laminating --- die cutting --- discharging waste material --- rolling the useful material, and this process will be done repeatedly upon your product's craft ship.

2. Machine description

1)ALL cutter holder's movements are controlled by JAPAN Omron servomotor with enough torsion ,stable acceleration and deceleration, precision can be ±0.05--±0.1.

2) All unwind & rewind shafts are driven separately by servo motors. The unwinding, rewinding, straight & reverse rotation are more flexible and controlled by high sensitivity tension sensor shaft's feedback to ensure smooth running.

3) It can save more 200 kinds of SOP data, improve standard level, and reduce dependence on Operator's experience and reduce more than 60% material waste

4) Main unwind EPC system can stabilize the material feeding into blade holder

5) Movable auxiliary unwind shaft

6) Fracturing detecting machine stop or alarming to reduce material waste.

7) Machine has the function of asynchronous laminating which can save material.

8) Color code electric eye tracking system can meet the demand of position precision of produce printing product.

9) The main operation interface adopts touch panel, with picture display for easy operation. Keyboard, mouse and hand touch are all available.

10) CCD testing system can test position precision all the time during the whole process and then feedback to PLC which send orders to servo motors to adjust position.

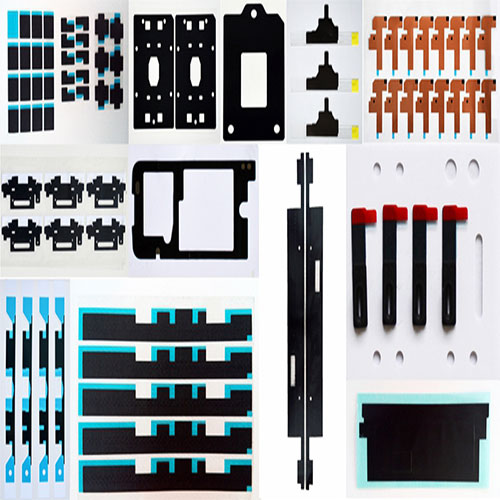

3. Application

Flexible PCB, Medical and Cosmetic, Anti Dust Foams Meshes, Conductive Insulation Pads, Graphite Thermal Pads, Screen Frame Adhesives, UHFHF RFID Tags Labels, etc.

4. After-sales

1) Engineers be dispatch to customers place for training and debugging

2) One year free warranty (except consumables), life paid maintenance and overseas service

3) Appointed account manager to help solve any problems at any time.

5. Customer Cases

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat