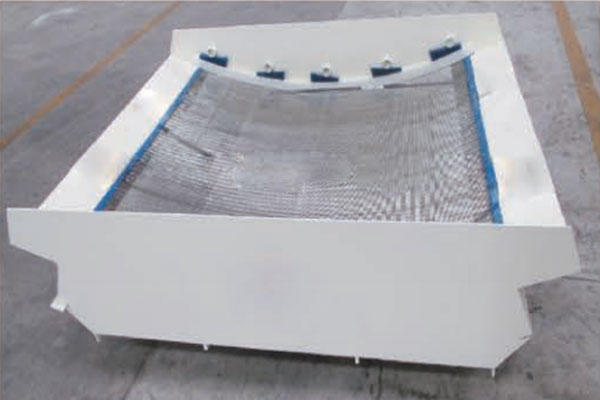

The curved screen screen is an optimized design that combines products from different manufacturers in the market. The design and manufacturing of the arc screen comply with the requirements of GB/T5000.3 mechanical design standard, JB/T2445-1999 coal arc screen and related coal preparation machinery industry standards. The selection, processing, welding, and assembly of all materials shall strictly comply with corresponding national standards. Fumat arc screen is widely used for material classification, dehydration, and demetrification.

operational principle

Fumart arc screen is mainly used for material grading, dehydration, and media removal in industries such as coal mines.

The material enters the screen surface at a certain speed along the tangent direction. Due to the centrifugal force, the material layer moves tightly against the screen surface. When the material layer flows from one screen bar to another, the edges of each screen bar have a cutting effect on the material layer. The cut material is discharged through the screen gap under the centrifugal force, becoming the underscreen material and falling into the underscreen chute;

The portion of material that has not been cut passes through the root sieve bars and becomes the sieve material, falling into the sieve material chute.

Product advantages:

Small installation space and simple structure;

Large processing capacity and high usage efficiency;

No moving parts, no noise generated;

Equipped with a rotating device, the screen surface can quickly change direction without disassembly;

The feeding box is specially designed, and the materials can be distributed on the sieve surface;

The curved stainless steel screen has sharp cutting edges and obvious dehydration effect;

The geometric shape of the screen surface wire section is good, which can be used for grading 0.25mm materials;

The specially designed screen surface wire can achieve a back width of 0.76mm and a screen gap of 0.35mm, effectively improving the opening rate and increasing the processing capacity.

Complete variety, able to fully meet the process requirements of different material characteristics and processing capacity, and can be specially designed according to user requirements;

We can provide various models of curved screen products with vibration.

Simple operation and maintenance, safe use, high cost-effectiveness, sufficient spare parts, and timely and thoughtful service.

A curved screen refers to a type of vibrating screen that has a curved or arc-shaped surface instead of a flat surface. This curved design allows for better distribution of material across the screen surface and improved screening efficiency.

The curved screen design helps to prevent material from accumulating in the corners or edges of the screen, reducing the risk of blinding or clogging. It also promotes better stratification of the material, meaning that particles of different sizes are more effectively separated and sorted.

Curved screens are often used in industries such as mining and aggregate processing, where they can handle high volumes of material and provide more accurate sizing and separation. They can be designed with single or multiple decks, depending on the application requirements.

In addition to their functional benefits, curved screens can also provide aesthetic appeal and a unique visual experience, especially in applications such as media and entertainment displays.

Overall, curved screens offer advantages in terms of improved screening efficiency, reduced blinding or clogging, and enhanced visual appeal compared to traditional flat vibrating screens.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat