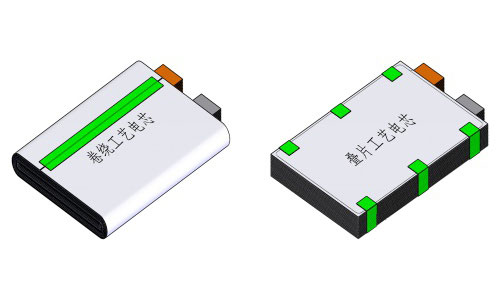

Renewable new energy batteries typically consist of several parts that can be produced using a die-cutting machine, including electrode sheets, separators, and insulation materials.

Electrode sheets parts are typically made from thin, flexible materials, such as copper foil and aluminum foil, which can be easily cut and shaped using die-cutting techniques. Die-cutting machines can be used to precisely cut these sheets into the desired size and shape, ensuring that they fit properly within the battery.

Separators are also important components of new energy batteries, as they help prevent short circuits between the anode and cathode. These separators are typically made of materials such as polyethylene terephthalate (PET), polypropylene (PP), and ceramic fibers. Die-cutting machines can be used to cut and shape these materials into the desired size and shape, ensuring that they fit properly within the battery.

Finally, insulation materials are used to prevent electrical contact between the anode, cathode, and other components within the battery. These materials are typically made of materials such as polyvinylidene fluoride (PVDF), polyethylene foam, PVC, and silicone rubber. Die-cutting machines can be used to cut and shape these materials into the desired size and shape, ensuring that they fit properly within the battery.

The advantages of rotary die-cutting and laser die-cutting machines for producing these parts include its high-speed production, high precision, and versatility as follows:

- High-speed production: Rotary die-cutting machines can produce parts at high speeds, making them ideal for large-scale production runs.

- High precision: Rotary die-cutting machines can achieve extremely precise cuts and shapes, ensuring that parts are manufactured to exact specifications.

- Versatility: Rotary die-cutting machines can handle a wide range of materials and thicknesses, allowing them to be used for a variety of battery parts.

- High precision: Laser die-cutting machines use a laser beam to cut and shape materials, resulting in extremely precise cuts and shapes.

- Flexibility: Laser die-cutting machines can be easily reprogrammed to produce shapes and sizes of parts, making them ideal for prototyping and small-scale production runs.

- Minimal waste: Laser die-cutting machines produce very little waste material, resulting in lower material costs and less environmental impact.

We compare rotary die-cutting machines, laser die-cutting machines, and traditional methods of producing battery parts, analyze some data on production speed, precision, flexibility, and material waste, and come out of each method has its own advantages and disadvantages:

Rotary die-cutting machines are ideal for large-scale production runs of battery parts, are typically the fastest method of producing battery parts, with production speeds up to 1,500 parts per minute.

They can produce parts at high speeds and with high precision, ensuring that each part is manufactured to exact specifications.

Round knife cutting machines can also handle a wide range of materials and thicknesses, making them versatile for different battery designs.

However, they may generate more material waste compared to other methods.

Laser die-cutting machines are highly precise and flexible, making them ideal for prototyping and small-scale production runs of battery parts, with production speed is at a rate of 100-500 parts per minute, depending on the complexity of the part.

They use a laser beam to cut and shape materials, resulting in extremely precise cuts and shapes.

Laser die cut machines can also be easily reprogrammed to produce different shapes and sizes of parts, making them versatile for different battery designs.

Additionally, they generate minimal waste, making them more environmentally friendly compared to other methods.

However, laser die cutter may have slower production speeds compared to rotary die cutter.

Traditional methods of producing battery parts, such as manual cutting and punching, may be suitable for small-scale production runs or for simple battery designs.

However, they are generally slower and less precise compared to rotary kiss-cutting machines and die-cutting machines with laser, with speed such as manual cutting and stamping, are much slower, with production rates of 10-20 parts per minute.

Additionally, they may generate more material waste compared to other methods.

Cost

Rotary cutting die equipment and traditional methods may be more affordable compared to laser die cutter.

However, laser die-cutting machines may provide more cost savings in the long run due to their precision and minimal waste.

Conclusion, the choice of method for producing battery parts will depend on factors such as production volume, precision requirements, material waste, and cost considerations.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat