what is a die cutting machine?

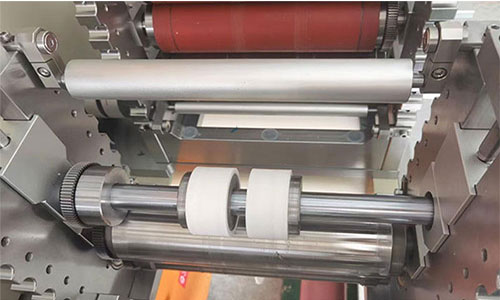

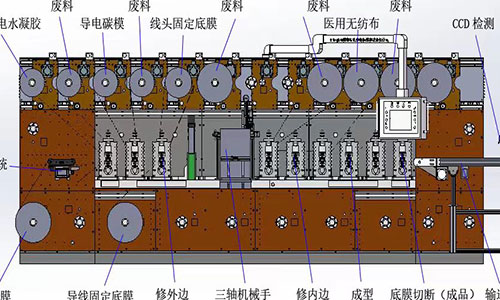

The traditional die cutting refers to a cutting process for the post-processing of printed matter. The die-cut process can produce printed materials or other paper products in accordance with the pre-designed graphics into a knife cutting plate for cutting, so that the shape of the printed material is no longer limited to the straight edge right Angle. Traditional die cutting production with die-cutter according to the product design requirements of the pattern combination die cutting plate, under the action of pressure, print or other plate blank rolling cut into the required shape or mark forming process. The indentation process is to use a wire cutter or a wire die to press out line marks on the sheet material through the action of pressure, or use a rolling wheel to roll out line marks on the sheet material, so that the sheet material can be bent and formed according to a predetermined position. Usually die cutting indentation process is the combination of die cutter and creasing cutter in the same template, the process of die cutting and indentation processing at the same time in the die cutting machine, referred to as die pressing.

With the rapid development of the electronics industry, especially the continuous expansion of the product range of consumer electronics, die-cutting is not only limited to the later cutting machine printing, but also the production of auxiliary materials for industrial electronic products. Common products are used in: electroacoustic, medical care, display signs, security protection, transportation, office supplies, electronic power, communications, industrial manufacturing, family leisure and other industries. Used in mobile phones, MID, digital cameras, automobiles, LCD, LED, FPC, FFC, RFID and other products, gradually used in the above products bonding, dust, shock, insulation, shielding thermal process protection and other aspects. The die-cutting materials used for processing are rubber, single and double sided tape, foam, plastic, vinyl, silicon, metal thin tape, metal sheet, optical film, protective film, gauze, hot melt tape, silicone, etc.

Die-cutting equipment is mainly divided into two categories: One is a large die-cutting machine specialized in carton color box packaging, the other is die cutter and embossing machine for precision electronic die-cutting products, the common denominator of the 2 is that they are fast punching products, need to use molds to complete, is an indispensable important equipment in modern technology, all kinds of cutting-die processes are based on the die-cutting machine produced, Therefore, the die-cutting machine closely related to us is the most important part of die-cutting.

Die cutting process flow: install die tools - plate - set machine pressure - debugging - paste sponge - die cutting pressure test - adjust pressure - die cutting production - waste removal.

Die cut is a comprehensive complexity in one of the cutting methods, involving human resources industrial equipment industrial process management and other projects, each need die cut manufacturers must attach great importance to, die cutting good and bad is directly related to the domestic industry technology production level, reasonable allocation of resources and bold attempt to new technology new equipment new concept is the professional spirit we need, Die-cutting industry's huge industrial chain continues to promote the continuous development of all walks of life, for the country's nationals play an important role, the future, the development of die-cutting is bound to be more scientific, more rational.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat