It is well known that protective films are an indispensable part of electronic products. Whether it is a mobile phone, a camera or a tablet computer, a protective film must be attached before leaving the factory to protect the screen of the product. The transparency, smoothness and cleanliness of the protective film affect consumers' impressions of electronic products. High-quality protective films can also enhance the external image of electronic products. Therefore, we have strict process control over the die-cutting process of protective film products.

After the protective film is printed, it needs to be formed on a round knife die-cutting machine. In the die-cutting process, it is necessary to avoid scratches and ink collapse. The specific manifestation of the ink collapse layer is that the ink layer at the edge of the product should cover smoothly, otherwise some phenomena of no ink will occur.

The main reason for ink collapse during die-cutting is that the adhesion between ink and material is not strong enough. When cutting the edge of the product, the ink layer will separate from the material, resulting in a serrated edge. Therefore, when printing protective film products, it is necessary to check the hardness of the ink to ensure that the ink is hard enough for die-cutting. In addition, when the thickness of the ink layer is too thick, ink collapse may also occur.

There are several reasons why scratches are easily produced during die-cutting. The most common reason is that the pressure roller rotates unevenly, causing relative sliding between the material and the roller to cause scratches. Therefore, it is necessary to ensure that the roller in contact with the material is flexible before checking the rotation of the roller. In addition, foreign objects on the drum can also cause scratches on the protective film, so it is necessary to use a clean cloth dipped in alcohol to wipe the roller before die-cutting to ensure that the roller surface is clean and free of foreign objects.

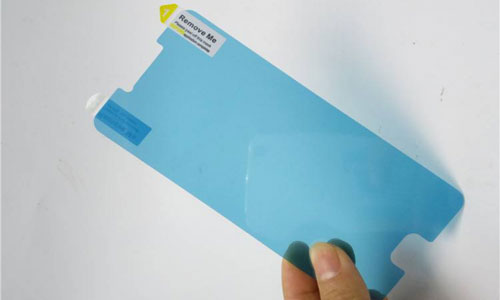

The die-cutting shape of the protective film is generally designed according to customer's drawings, mainly based on the screen size of the customer's mobile phone products, usually a rectangular shape with rounded corners, with a handle at the lower right corner of the rectangle printed on the back. Then a layer of PET is added for easy customer assembly and for consumers to remove the protective film from the screen. All kinds of protective films are produced using round knife die-cutting machines, but when the process is complex, the number of round knives that need to be used will increase. For example, a protective film that needs to attach a handle requires two round knives, one for cutting the handle and the other for cutting the outside.

Although the production process of mobile phone protective films seems simple, each step has strict requirements. Generally speaking, we must always pay attention to cleanliness to avoid curling and scratches on the protective film. It is the above details that determine the level of the product.

A good mobile phone protective film is also inseparable from high-quality production machines. If the machine is not selected properly, the above-mentioned problems will occur frequently, especially when the machine works at high intensity, so it is necessary to purchase high-quality round knife die-cutting machines.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat