New energy vehicles have become an important trend in the future automotive industry. Reducing average power consumption and improving driving range are among the research directions that the industry is constantly exploring. Issues such as driving range, charging, and safety, which have attracted much attention, ultimately depend on the performance of the "heart" of the vehicle - the power battery.

So, how can we "turn the tide" and achieve ✅greater stability✅more reliability✅enhanced safety✅greater environmental friendliness on the existing basis?

Starting with replacing traditional harnesses

The power battery PACK always encounters these headaches: messy harness wiring, occupying space in the battery pack, relying on manual assembly, and difficult to achieve large-scale automated production.

As the "nervous system" of new energy vehicles, lightweighting harnesses are increasingly important for reducing energy consumption per vehicle. Currently, leading enterprises such as CATL, BYD, Tesla China, Guoxuan High-Tech, and AVIC Lithium Battery are all adopting FPC solutions to replace traditional harness solutions.

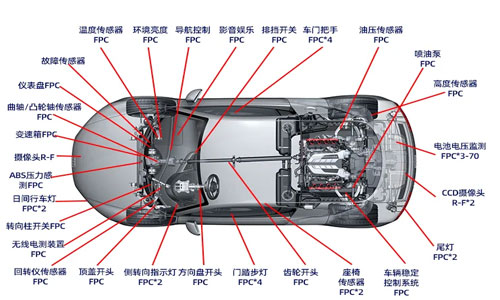

▲ The application of FPC in automobiles

What is FPC?

FPC: English full spell Flexible Printed Circuit, Chinese means flexible printed circuit board, referred to as soft board. The collection line is an important part of the BMS system of new energy vehicles to monitor the voltage and temperature of the new energy power battery cell; Connect data acquisition and transmission with overcurrent protection function; Protect the car power battery cell, abnormal short circuit automatically disconnect and other functions.

Previously, the new energy vehicle power battery collection line used the traditional copper wire harness scheme, the conventional wire harness is formed by the copper wire surrounded by plastic, and each wire harness reaches an electrode when the battery pack is connected. When the power battery pack current signal is many, many wire harnesses are needed to match, and the space is crowded.

In the Pack assembly process, the traditional wiring harness relies on workers to manually fix the port on the battery pack, and the degree of automation is low. Compared with copper wire harness, FPC has outstanding advantages in safety, lightweight and regular layout due to its high integration, ultra-thin thickness and ultra-flexibility. In addition, FPC has thin thickness, customized battery pack structure, and can be grabbed and placed directly on the battery pack by mechanical arm during assembly, which is highly automated and suitable for large-scale mass production. The trend of FPC replacing copper wire harness is clear.

Vehicle FPC consumption exceeds 100 pieces, the number and area of power battery FPC far exceeds the original vehicle FPC, and the great development of new energy vehicles has driven a substantial increase in the demand for FPC for vehicle power batteries.

FPC should have the following advantages in the power battery module:

Highly integrated: self-embedded Fuse, connector, chip NTC, aluminum/nickel terminals; It not only provides excellent and consistent electrical performance, but also can meet the design requirements of smaller and higher density installation with three spatial wiring and the appearance can be changed according to the limitations of space, which is suitable for the development of high-density, miniaturization and high reliability, so as to achieve the integration of component assembly and wire connection.

Automatic assembly: fast and accurate assembly, which is conducive to automation; In the assembly and fault tolerance here, you can avoid a lot of manual errors in the harness design, and reduce a lot of opportunities for insertion errors at the connector level. Using FPC sampling, the Module integration process complexity can be reduced, and the connection between FPC and battery busbar can be automated welding, effectively reducing labor costs. Even if the customer is unable to mature automatic welding, the traditional screw locking method can still effectively reduce the manual input.

Ultra-thin thickness: 0.34mm in line area, 2mm in NTC.

Ultra-soft: the line area can be bent and assembled at 90° and 180°.

Lightweight: When the whole vehicle is used, the weight can be reduced by about 1kg compared to the wiring harness scheme.

Cost advantage: From the cost point of view, the cost of FPC itself is not high, for the connection cost, there is a great reduction.

The global automotive BMS soft board market penetration has increased, promoting market expansion. Compared with traditional wiring harnesses, automotive BMS soft board has advantages such as safety, lightweight, flexible process and automated production. New energy vehicles such as Tesla and BYD lead FPC solutions to replace traditional wiring harnesses, and the penetration rate of BMS soft board solutions is expected to continue to increase. We expect to further increase from 14% in 2021 to 70% in 2025, assuming that the value of automotive BMS soft board bicycles in 2021 is 800 yuan/car, and the average annual unit price is reduced by 5%. The corresponding BMS soft board market space will rise from 690 million yuan in 2021 to 10.69 billion yuan in 2025.

FCCL materials are in urgent demand

All processing of FPC is done on FCCL. FCCL is the key substrate for the production of FPC, and the cost accounts for 40%-50%.

FCCL is mainly made of rolled copper foil, polyimide (PI) film or polyester (PET) film substrate film and adhesive, and the substrate PI film is its core raw material.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat