What is ferrite?

Ferrite is a metallic oxide with ferromagnetic properties. In terms of electrical performance, ferrite has a much higher resistivity than metallic and alloy magnetic materials, and it also has high dielectric properties.

The magnetic performance of ferrite also shows high permeability at high frequencies. Therefore, ferrite has become a widely used non-metallic magnetic material in the field of high frequency and weak current. Due to the low magnetic energy stored in a unit volume of ferrite, the saturation magnetization intensity is also low (typically only 1/3 to 1/5 of pure iron), which limits its application in low-frequency high-power electrical fields.

Difficulties in die cutting ferrite materials

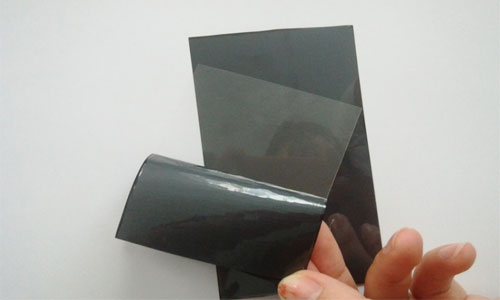

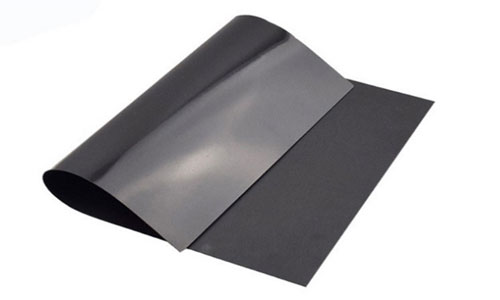

This material is basically in sheet form, with a thin thickness, relatively heavy weight, and high brittleness. It will break when you lift it with your fingers. Under normal stress conditions, the fracture does not follow the direction of the applied force. If double-sided chamfering like graphite sheets is to be performed, the main processing difficulties are as follows:

1. Difficulty in extracting and feeding raw materials;

2. How to achieve batch automatic order placement;

3. Positioning die cutting is required to avoid gaps, glue residue, and ineffective positioning;

4. The holes in the product must be punched as a whole segment, which is not easy to discharge and affects the tool's service life.

5. The handle colors must be distinguished and punched.

So, how to die-cut this difficult-to-process material? Today, we will provide a technical analysis of the wireless charging ferrite die cutting process for everyone. If you have better comments, please leave a message and share them with us!

Ferrite die cutting process steps

1. Laminating ferrite material

A three-position laminating machine is used to laminate the ferrite material! The structure is a top protective film layer, single-sided adhesive-bonded ferrite material, double-sided adhesive tape, and the bottom layer is a bottom protective film!

2. Punching and punching the inner hole of the product

After the product passes through the three-position laminating machine, it enters the high-speed die cutting machine to punch the inner hole and outer frame of the product!

3. Polyester film die cutting and laminating the handle

After punching the positioning hole and outer frame from the high-speed die cutting machine, the product enters the three-position laminating machine to remove the waste outer frame and cover the handle!

4. Die cutting, punching, and cutting the entire material frame

After laminating the polyester film handle, flip the material and enter the high-speed die cutting machine, then punch the entire frame on the second cut and process a part of the product!

5. Die cutting, waste removal, and slicing of the outer frame

After punching, the material enters a two-position laminating machine, and waste is discharged from the frame of the entire sheet product! Finally, the product enters the slicing machine for electromagnetic induction slicing. The final product is in sheet form!

A good round knife die-cutting machine can produce high-quality ferrite sheets, making the die-cutting process smoother.

Rotary Die Cutting of Ferrite Materials

Die cutting is a versatile manufacturing process used to shape materials efficiently and precisely. One application of die cutting is the fabrication of rotary shapes from ferrite materials. Ferrites are magnetic materials that have a wide range of applications in electronics, telecommunications, and other industries. This article will explore the process of rotary die cutting with ferrite materials, highlighting its benefits, considerations, and applications.

1. Advantages of rotary Die Cutting with Ferrite Materials:

rotary die cutting offers several advantages when working with ferrite materials:

a. Precision: Die cutting ensures accurate and consistent cutting of rotary shapes with tight tolerances, meeting the requirements of different applications.

b. Efficiency: rotary die cutting can be automated, enabling high-volume production and reducing labor costs. It allows for rapid production cycles and eliminates the need for time-consuming manual cutting.

c. Versatility: Die cutting can be applied to various ferrite materials, including soft ferrites and ceramic ferrites. This versatility allows for the creation of rotary shapes for different purposes.

2. Considerations for rotary Die Cutting of Ferrite Materials:

a. Tooling: Choosing the right rotary cutting die is crucial. The die should be designed to match the desired rotary shape and material thickness. Proper tooling selection ensures clean cuts and minimizes material waste.

b. Material Properties: Ferrite materials exhibit different physical properties, such as hardness and brittleness. These properties influence the die cutting process, including the choice of cutting speed, pressure, and blade material to avoid material damage and achieve smooth edges.

c. Post-processing: After die cutting, ferrite materials may require additional finishing processes like deburring or polishing to achieve the desired surface quality and dimensions.

3. Applications of rotary Die Cut Ferrite Materials:

a. Magnets and Inductors: rotary die-cut ferrite materials are commonly used in the production of magnets and inductors. These components play a vital role in electrical devices, transformers, and power supplies.

b. Communication Devices: Ferrite materials are used in various communication devices, such as antennas and filters. rotary die cutting enables the efficient production of these components with specific geometries and dimensions tailored to the application requirements.

c. Electronics and Automotive Industries: rotary die-cut ferrite materials find applications in electronic shielding, signal transmission, and noise suppression. Moreover, they are utilized in automotive electronics, such as ignition systems and electric power steering.

rotary die cutting is a valuable technique for shaping ferrite materials into precise rotary shapes. It offers advantages in terms of precision, efficiency, and versatility. By considering key factors like tooling, material properties, and post-processing, manufacturers can optimize the die cutting process and produce high-quality rotary ferrite components for a wide range of applications in industries such as electronics, telecommunications, and automotive.

Welcome to pay attention to Fumart round knife die-cutting machine.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat