Foam materials come in various types, such as EVA foam, PE foam, and PU foam. Each type of foam has its own specific characteristics. Let's take a brief look at the differences between EVA foam and PE foam.

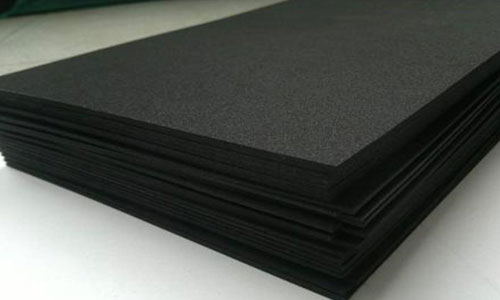

Characteristics of EVA foam:

EVA foam is a new type of environmentally friendly plastic packaging material. The EVA rubber and plastic products are designed and processed to have better shock resistance compared to traditional packaging materials such as polystyrene (foam). EVA foam can be cut and molded, and it has a wide range of applications due to its varying densities. It meets environmental protection requirements and has good moisture resistance, thermal insulation, cushioning, chemical corrosion resistance, and seismic resistance. Additionally, EVA foam does not absorb water and is non-toxic.

What are the differences between EVA foam and PE foam?

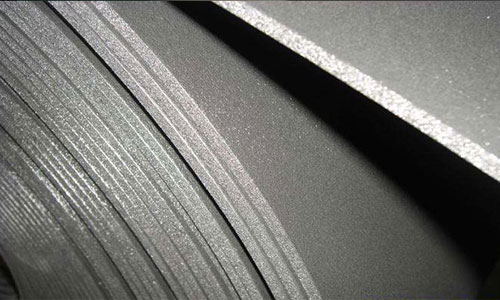

Characteristics of PE foam:

PE foam is made from polymer foam material as the base material coated with high-performance pressure-sensitive adhesive (acrylic or rubber-based adhesive) on both sides, and it is compounded with single or double silicone release material. PE foam comes in various thicknesses, densities, shapes, and colors, allowing for multiple options. Due to its excellent weather resistance, chemical resistance, cushioning, sound absorption, and superior adhesion, PE foam is suitable for applications in industries such as electronics, household products, automotive interiors, medical protection, and precision machinery.

In conclusion, EVA foam and PE foam have differences in terms of material, uses, and performance characteristics. Therefore, it is important to consider these factors when choosing foam materials. We hope this information can be helpful to those who need it. Follow Fumart Cutting Machine to stay updated on industry trends.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat