New energy die-cutting is a cutting-edge technology that plays a pivotal role in the field of renewable energy. It involves precision cutting and shaping of various materials used in the production of clean energy technologies such as solar panels, wind turbines, and fuel cells. Through the use of advanced die-cutting machinery and techniques, manufacturers are able to create intricate and customized components that are essential for the efficient functioning of these energy systems.

One of the key benefits of new energy die-cutting is its ability to optimize the performance and durability of renewable energy devices. By accurately shaping and cutting materials to precise dimensions, die-cutting ensures the highest level of efficiency in converting natural resources into electricity. This technology enables the production of components that fit seamlessly into renewable energy systems, maximizing their power output while minimizing energy loss.

Furthermore, new energy die-cutting also contributes to cost reduction and enhanced sustainability in the renewable energy sector. It allows manufacturers to efficiently process raw materials and optimize material usage, reducing waste and increasing overall production efficiency. This not only leads to financial savings but also promotes a greener and more sustainable approach to energy production.

In conclusion, new energy die-cutting is revolutionizing the renewable energy industry by enabling the precise manufacturing of components necessary for the seamless operation of clean energy technologies. This technology not only enhances the performance and durability of renewable energy systems but also promotes cost reduction and sustainability. As the demand for clean energy continues to rise, new energy die-cutting will undoubtedly play a vital role in shaping the future of renewable energy.

With advancements in technology, policy support, and increasing market demand, new energy will play an increasingly important role in energy supply, transportation, and energy storage technologies. This also implies that die-cutting technology is becoming more and more important. Die-cutting technology enables high-precision cutting and shaping of key materials, as well as reliable assembly and connection, good sealing and isolation performance. Currently, the common die-cutting applications in the field of new energy are as follows:

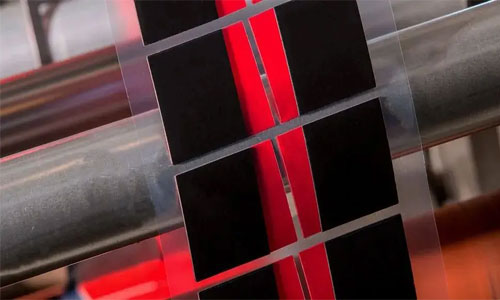

1. Photovoltaic Cells: Photovoltaic panels are the basic materials for solar photovoltaic modules. In the manufacturing process, precise trimming and shaping, such as deburring and dividing large silicon wafers into smaller ones, are required. Die-cutting technology can achieve precise cutting and shaping of photovoltaic cells using precision molds, ensuring dimensional accuracy and smoothness.

2. Lithium Battery Separator: The lithium battery separator is an important component of lithium-ion batteries, used to isolate the positive and negative electrodes and prevent battery short-circuits. Die-cutting can accurately trim and shape the lithium battery separator to improve product stability and safety.

3. Fuel Cells: As a new clean energy, fuel cells are gradually being popularized. One of the core components of a fuel cell is the electrolyte membrane, which needs to be shaped and cut using die-cutting technology. Other components of fuel cells, such as polymer electrolytes and electrodes, also require die-cutting processing.

4. LED Lighting Products: LED lighting products are more energy-efficient and environmentally friendly than traditional lighting products. Precise shaping and cutting are required during the manufacturing process. For example, LED light strips, LED displays, and LED modules need to be processed using die-cutting technology to ensure stability and efficiency.

5. Automotive Electronics: With the development of the automotive industry, more and more automotive components require the use of electronic components. These components need to be designed in small size and lightweight, thus requiring die-cutting processing. For example, automotive instrument panels, navigation screens, and audio panels need to be shaped and cut using die-cutting technology to ensure stability and safety.

6. Flexible Electronics Manufacturing: Flexible electronic devices have wide applications in the field of new energy, such as flexible solar cells and wearable devices. Die-cutting technology can be used to cut and shape flexible electronic materials to achieve the desired shape and size.

New energy products have higher requirements for die-cutting precision and quality, so it's important to choose a suitable and professional die-cutting service provider.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat