Speaking of professional product terms in the die-cutting industry such as OCA optical adhesive and foam adhesive, many friends may find them unfamiliar, but insiders will blurt out double-sided adhesive, foam, earpiece mesh, LCD internal enhancement, diffusion, OCA etc.

Today in the 21st century, die-cut products are widely used in industrial control products, electronic products, medical masks, household appliances, daily necessities and other fields, among which we are more familiar with mobile phone screen protectors. Today we will reveal the hidden corners of the die-cutting industry for you, and see how die-cutting products are applied in various fields!

1. Application of die-cut products in the fields of batteries, casings and new energy

It is used for stamping of lithium battery pole piece, collection line, ccs, flexible circuit board, battery insulation sheet, highland barley paper, chassis, lithium battery general insulation pad, solar pole piece, sun protection film, etc., to insulate and buffer them effect.

2. Application of die-cut products in the field of mobile devices

1) Mobile device

Mobile phones are the most widely used fields for die-cut products. The operation of mobile phones is becoming more and more intelligent, and the body is getting thinner and thinner, all of which are inseparable from the continuous innovation of die-cutting technology and the support of ultra-fine processing technology. Look at the parts that need die-cutting technology in the field of mobile phones: protective film, touch screen, display screen, backlight film, window, black and white glue, lens protection, nameplate, serial label, earphone/microphone O-ring fixation, earphone/microphone dustproof Net, window/microphone dust pad, earpiece/microphone cushion, earpiece/microphone dust pad, PCB fixing board, LCD reflective film, backlight, battery compartment, battery label.

2) Tablet devices

Tablet PC is another device field that is most closely related to the die-cutting industry after mobile phones. The trend of tablet computers replacing notebooks is inevitable, and the increasingly humanized and intelligent tablet devices are also closely related to the die-cutting process. So, what are the components used in the die-cutting process for tablet devices? As follows: protective film, touch screen, display screen, touch screen gasket, touch screen fixing rubber pad, display fixing rubber pad, camera lens, motherboard, port insulation protection layer, top cover, signage, microphone dustproof net, LED board, FPCB fixing, Battery compartment fixation, battery compartment cushion, window fixation, microphone dust filter, microphone cushion, microphone dust filter, key switch, backlight.

3) Smart watch device

Recently, the hot smart watch products are still a field where die-cutting products are widely used. Behind the shining of smart watches in the world again and again, it is also inseparable from the support of more cutting-edge and high-precision die-cutting technology.

Watch straps, screen protectors, touch screens, displays, circuit boards, backlight components, dust filters, battery interfaces and other soft board components.

3. Application of die-cutting products in the field of digital equipment

All kinds of digital products are flooding our world, and die-cutting technology is ubiquitous in life and work.

Cameras, camcorders, digital cameras, digital audio equipment (such as movie theaters, music players, etc.), MP3, MP4, MP5, voice recorders, scanners, DVD players, memory cards, mother-in-law phones, set-top boxes, satellite receivers, TVs Die-cutting equipment is used in the production and processing of machine tools and CNC home appliances.

Take a digital camera as an example:

A. Rubber pad

B. Protection of PCB

C. Flash card

D. Fixing of LCD buffer pad

E. Fixing of buttons and hard materials

F. Fixing of the mirror cover

G. Fixing of the flash battery/cushion pad

H. Fixing of reflective mold

I. Fixing of the battery board

J. Fixing of LCD module

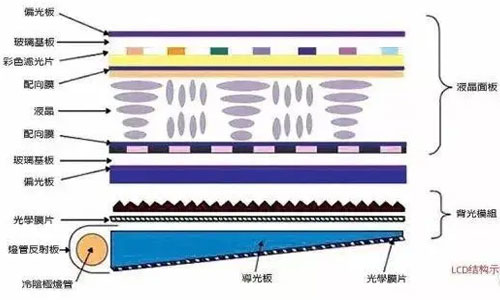

4. Application of die-cut products in the field of LCD equipment

The invention and popularization of LED and LCD display devices have made our world more colorful and visually richer. Similarly, continuous innovation in this field is also inseparable from the support of die-cutting equipment.

It is used in liquid crystal optical films, polarizers, backlights, various rubber pads, reflectors, diffusers, and light-shielding tapes at the components of rear projection lamps, for dust-free microfabrication in clean rooms.

5. Application of die-cutting products in the field of electronic medical care

Medical supplies: hemostatic patches, medical masks, antipyretic patches, capsule plates, packaging boxes, western medicine paper bags, etc.

Maternal and baby products: diapers, sanitary napkins, nursing pads, urine pads, bibs, etc.

6. Application of die-cut products in the field of transportation

Used in automobile dial panel parts, gaskets for carriages, sponge materials, explosion-proof membranes, shockproof pads, vehicle touch screen navigation equipment, copper foil, aluminum foil and brake parts, etc.

7. Application of die-cut products in the field of paper materials

Office supplies: copy paper, release paper, backing paper, sticky notes, notebooks, bills, requisition forms, leave forms, invoices, reports, etc.

Supermarket paper: labels, price stickers, shopping receipts, product name stickers, promotional stickers, etc. the

Industrial paper: used to make paper or cardboard such as cartons, cartons, paper cups, and paper plates, such as kraft cardboard, corrugated medium paper, coated white cardboard, gray cardboard, etc.

8. Application of die-cut products in the field of adhesive

AB glue, 3M, TESA, black and white glue, self-adhesive, double-sided tape, easy-to-tear stickers, conductive cloth, PE foam glue, PET film, PVC film, electrostatic film, blue film, insulating materials (PVC sheet, PET sheet , Kuaiba paper, green shell paper, high temperature resistant insulating glue)

9. Application of die-cut products in the field of clothing

Velcro, hang tags, trademarks, collar pads, shoulder pads, elastic bands, rubber bands and other garment accessories processing.

10. Application of die-cut products in the field of small household appliances

Electric toothbrushes, die-cut parts of some small household appliances such as beauty, blood sugar and blood pressure testing.

In summary, the die-cutting industry covers a wide range of fields, and as products become more humanized and sophisticated, die-cutting products will be more widely used in different fields, and the relationship between materials and processing manufacturers will also become more and more the tighter.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat