With the arrival of the 5G era, new technologies are emerging, leading to more possibilities in the design of consumer electronics products. As the most widely used area for die-cut products, the development of consumer electronics products has driven the development of die-cut parts.

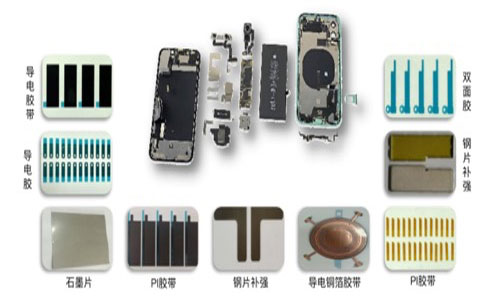

Components that require die-cutting technology in the mobile phone field:

Protective film, touch screen, display screen, backlight film, window, black and white glue, lens protection, nameplate, serial label, earphone/microphone O-ring, earphone/microphone dustproof net, window/microphone dustproof pad, receiver/microphone cushion, receiver/microphone dustproof pad, PCB fixing plate, LCD reflective film, backlight, battery compartment, battery label, conductive tape, conductive glue, graphite sheet, PI tape, steel sheet reinforcement, conductive copper foil tape, double-sided tape, etc.

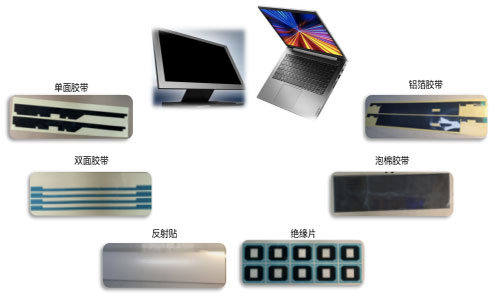

Components that require die-cutting technology in the display field:

Optical film, polarizing film, backlight source, various adhesive pads, reflective plate at the backlight lamp component, diffusion plate, light-shielding tape, waterproof foam double-sided tape series, sandwiched PET double-sided tape (transparent/black), transparent PET single-sided tape, black PET single-sided tape, aluminum/copper foil tape, etc.

Components that require die-cutting technology in the FPC field:

The production process of FPC is complex, requiring more than 20 processes from material cutting and drilling to packaging and shipping. During this lengthy production process, various auxiliary materials are used according to customer requirements. The substrate of FPC is generally double-sided or single-sided copper foil, which is the foundation of the entire FPC and determines its electrical performance. Other auxiliary materials are used to assist in installation and adapt to the operating environment. Mainly include PI tape, steel sheet, TPX resist film, EIM electromagnetic film, conductive adhesive, single-sided adhesive conductive cloth, double-sided adhesive fixing, reinforcement steel sheet, shock-proof foam, conductive double-sided adhesive, PI film, etc.

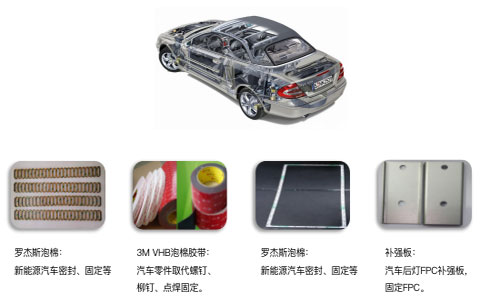

Components that require die-cutting technology in the automotive field:

Die-cut products such as damping aluminum foil tape, electrical adhesive tape, foam tape sealant, die-cut products for rearview mirror base structure adhesive tape, die-cut products for specific sound-absorbing materials, die-cut products for in-car display LCD, VCD, and DVD, die-cut products for transfer tape for in-car components, die-cut adhesive tape for various interior components, die-cut products for protective buffer materials, die-cut products for roof structure sealing tape, waterproof foam double-sided tape series, aluminum/copper foil tape, Rogers foam, VHB foam tape, and various washers.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat