Protective films have become a very important industry in the new era, especially in mobile phone protection films, where PET protection films are used for phone screens and casings. PET protection films can be divided into PET silicone protection films and PET acrylic protection films. Professionals can easily distinguish between silicone protection films and acrylic protection films, but for those who are new to the industry, it can be difficult to differentiate. Some customers may not even know whether they need acrylic protection film or silicone protection film.

Silicone Protection Film

First, let's understand the performance differences between acrylic protection films and silicone protection films. Currently, most of the PET protection films we use are made with silicone, and PET protection films with silicone are widely used. For example, PET protection films with silicone are now widely used for mobile phone screens and can withstand higher temperatures. Acrylic protection films, on the other hand, are mainly used for packaging high-gloss products and thin film switches. They are a cheaper and easier-to-use film.

Acrylic Film

When we obtain PET protection film products, how can we differentiate between acrylic protection film and silicone protection film?

1) The simplest and quickest method is to scratch the adhesive surface of the protection film with your fingernail. Silicone protection film does not produce glue or powder, while acrylic protection film will produce white powder and glue. Due to this feature, silicone protection film is also known as non-powder adhesive.

2) Differentiate by smell: silicone protection film is odorless, while acrylic is not.

3) After burning, silicone protection film turns gray, while acrylic protection film turns into a liquid state.

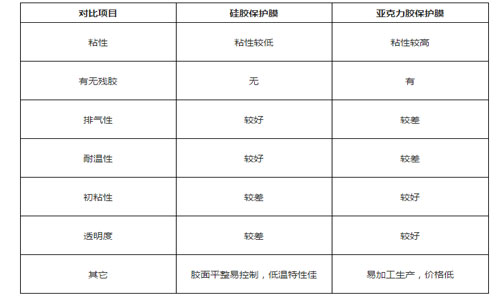

In addition, there are differences between PET silicone protection film and PET acrylic protection film:

1) Acrylic adhesive has high viscosity and will leave residue after peeling off, while silicone has lower viscosity.

2) When placing the protective film on the surface of the object to be adhered, gently touch it with your finger. If there are almost no bubbles or very few, it is likely silicone protection film. Acrylic adhesive is slower to bond.

3) In terms of transparency, acrylic is superior to silicone.

4) Silicone has good heat resistance, is easy to control the flatness of the adhesive surface, and has excellent low-temperature performance. Acrylic adhesive is easy to produce and process, has good transparency, low price, good weather resistance, and high viscosity.

Comparison of Characteristics between Silicone Protection Film and Acrylic Protection Film

Acrylic protection film has a wide range of applications, and its viscosity can be high or low, making it suitable for many products at a lower price.

Silicone protection film, due to its exhaust function, is mainly suitable for glass surfaces or high-gloss surface products. This type of protective film performs well under high and low temperatures, but the price is slightly higher.

Scratching acrylic adhesive will cause powder to fall off, while silicone does not produce bubbles and is easy to produce ghosting.

Therefore, when choosing manufacturers of acrylic protection film, consider whether the surface protection film has the following characteristics and compatibility with the protected object:

1. The acrylic protection film manufacturer should make the surface of the protected material inert, without reacting with the surface, corroding, or contaminating it.

2. The acrylic protection film has good adhesion to the protected material. During material handling and processing, the protective film will not warp or fall off. Nowadays, many protection films have self-adhesiveness or static adsorption, which can adhere very well to the surface of the object.

3. The acrylic protection film has good weather resistance and adhesive stability. After several days or long-term use, the peel strength will not significantly increase, and it is easy to peel off. When peeling off the protected surface, no residual adhesive will be left.

4. The acrylic protection film has good processing adaptability and can meet the deep processing needs of the protected object.

Protective films may seem simple, but the production process is actually quite complex, and each step has strict requirements, especially the control of die cutting technology. Only high-quality die-cutting machines can produce high-quality products and reduce waste and costs to some extent. If you want to learn more about technical issues related to die cutting production or need guidance on how to choose a rotary die cutting machine, please feel free to contact industryprocess, Fumart. We are always here to serve you.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat