In many materials, some people often cannot tell similar materials apart, such as stretch film and protective film. Many people confuse the two of them, so today we will talk about the differences between them.

Generally, stretch film is filled with adhesive additives, such as PIB masterbatches. It is processed by casting, and the surface is a bit sticky and can stick to itself. The main purpose is to wrap objects and fix them.

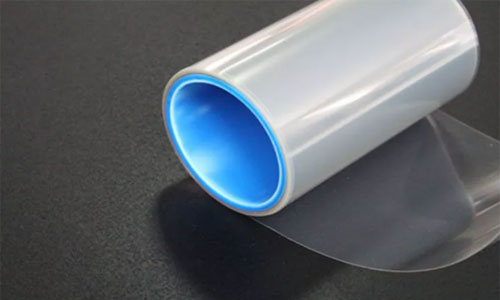

Protective film comes in many forms, the most common of which is a layer of glue applied to the surface of a blown polyethylene film, just like transparent tape in daily life. The main purpose is to protect the surface of solids, and it can be removed when it is no longer needed. In short, stretch film is self-adhesive, while protective film has a layer of glue on the surface of the film.

Stretch film and protective film are quite similar to the plastic wrap we commonly use for food preservation, but the difference is that stretch film is industrial-grade, while plastic wrap is used for food.

The protective film is the type used on our phone screens, which is a transparent, elastic, non-toxic, and harmless soft polyethylene plastic film that meets international environmental and health standards. It can be cold-stretched vertically and horizontally without the need for heating. It can be self-adhesive and package various products to maintain the tension of the goods for a long time.

The differences between stretch film and protective film are:

1. The materials are the same, but the process is different. Stretch film is made of polyethylene, which is tough and not easily crushed by ordinary plastic crushers, while protective film is mainly made of polyethylene, which is made by polymerization reaction. Depending on the materials and plasticizers used, protective films can be divided into many types suitable for different occasions.

2. Different uses. Stretch film is mainly used for the sales and transportation of alcoholic beverages, canned goods, mineral water, various beverages, cloth, non-food, and pharmaceutical packaging, while protective film is mainly used for microwave food heating, refrigerator food preservation, and fresh-cooked food packaging. In household life, it is used in supermarkets, hotels, and food packaging in industrial production.

3. Different environmental protection concepts. The PE material of stretch film can reduce air pollution, waste disposal, recycling and overall packaging costs, but some protective film manufacturers use PVC materials. At room temperature, this plasticizer can penetrate into fatty packaged foods, causing great harm to the human endocrine system.

When choosing stretch film and protective film, you must pay attention to distinguish between them, as there are significant differences between the two.

Fumart circle cutting machine is mainly used in the electronic cutting industry, and production of various protective films could not be separated from it. It is a cost-effective brand of circle cutting machines on the market.

Fumart circle cutting machine is a type of die-cutting machine called the multi-station rotary die-cutting machine, also known as a circle cutting machine, rolling knife machine or multi-station rolling knife machine. It continuously rotates for die-cutting processing in a circular form, which is one of the high-efficiency machine types among die-cutting machines. It has various models such as 2-position, 3-position, 5-position, 7-position and other circle cutting machines (collectively called multi-station circle cutting machines).

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat