Insulating flame-retardant PC film plays a crucial role in the application of new energy batteries, offering significant advantages in terms of safety and performance.

Insulating flame-retardant PC film acts as a protective barrier, ensuring that the battery cells are securely enclosed and isolated from external factors. Its excellent insulating properties prevent electrical leakage and minimize the risk of short circuits, enhancing the overall safety of the battery system.

Moreover, the flame-retardant characteristics of PC film provide an added layer of protection in case of thermal events or accidents. It effectively retards the spread of flames, reduces the release of toxic gases, and contributes to suppressing fire hazards, giving an extra level of safety to the battery pack.

In addition to its safety features, PC film also offers excellent mechanical strength and dimensional stability. It maintains its integrity even in harsh operating conditions, such as high temperatures or vibrations, ensuring reliable and durable performance in the battery system. Its dimensional stability helps to prevent deformation or shrinkage of the film, ensuring consistent contact with battery components for optimum efficiency.

Furthermore, the transparency of PC film allows for easy inspection and monitoring of the battery cells, facilitating the detection of any potential issues or abnormalities. This transparency enables effective quality control processes and enhances the overall maintenance and management of the battery system.

Overall, the application of insulating flame-retardant PC film in new energy batteries provides a robust and reliable solution. Its combination of insulation, flame retardancy, mechanical strength, and transparency contributes to the safety, performance, and longevity of the batteries, fostering the advancement of the new energy industry.

PC (polycarbonate) is the fastest growing general-purpose engineering plastic among the top five engineering plastics. It has excellent impact resistance, good creep resistance and dimensional stability, heat resistance, low water absorption, non-toxicity, and excellent dielectric properties. It is widely used in industries such as electronics and electrical appliances, sheet/film, automotive industry, and construction.

Among them, insulated and flame-retardant PC film/sheet is mainly made of PC polycarbonate and halogen-free flame retardant additives. It is processed through extrusion and calendering methods, including raw material drying, melting and plasticizing, three-roll calendering, cooling and shaping, cutting and stacking, and product packaging.

Insulated and flame-retardant polycarbonate PC film has excellent flame retardancy, heat resistance, high voltage resistance, low water absorption, bending resistance, tear resistance, and is not easily broken. It can be used in new energy vehicle battery modules, battery cells, PACK, etc.

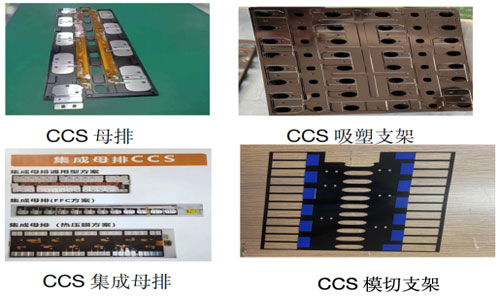

CCS Application: CCS vacuum forming bracket and CCS die-cut bracket

There are mainly two schemes for using PC film in CCS:

Scheme 1: PC film is vacuum formed into CCS vacuum forming bracket, and then integrated with signal acquisition components and aluminum bars through riveting process.

Scheme 2: PC film is die-cut and directly bonded with adhesive to make CCS bracket, and the aluminum bar is integrated by pasting it on the PC die-cut bracket.

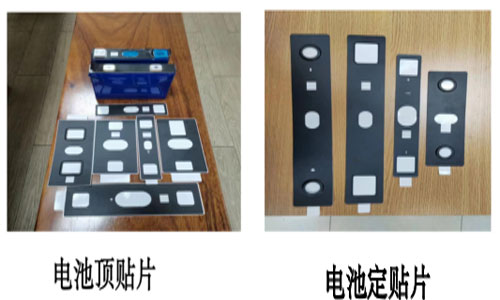

Battery Cell Application: Used for positive and negative electrode top patches

PC film is processed by die-cutting with adhesive to achieve the desired effect for each battery type, and it is attached to the top and bottom of the battery shell.

PACK Application: Battery pack cover board

PC film is mainly used for insulation between battery cells inside the PACK and insulation between the battery cells and the aluminum shell.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat