Foam is a common material in die cutting processing and is well known to the public. In fact, foam can be divided into different types based on its material and characteristics. Through die cutting processing, foam can be utilized to its fullest potential to meet the needs of different industries. Now, let Cutting Home take you through an analysis of the processing technology of EVA foam die cutting.

In the die-cut parts we process, EVA foam die cutting is often encountered, with a thickness ranging from 1-2mm and possibly reaching up to 5mm. In the production process of EVA foam die cutting, there are bound to be various issues or problems. The main problems we frequently encounter can be summarized into the following three points:

Slanted edges during foam punching (large bevels in circular knife cutting).

2. Easy generation of foam debris during the stamping process.

3. Difficulty in discharging waste material for some hole-shaped products (small hole diameter, large foam thickness, and difficult waste material discharge).

These are common phenomena in EVA foam die cutting operations. Next, let's analyze these three common problems and provide corresponding solutions. EVA foam has its own characteristics. Let's briefly introduce them: EVA foam die cutting has a high thickness, a certain elasticity, a low elastic limit, and is prone to powdering. Given the above-mentioned characteristics of EVA foam die cutting process, there will be three basic problems:

1. Reduction in pressure during EVA foam die cutting:

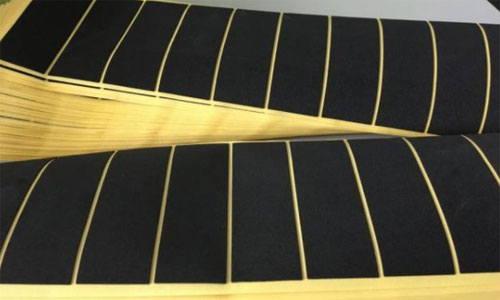

Firstly, regarding the slanted edges that may occur during die cutting and punching processes, the main cause of this issue is the high thickness of the foam. During the stamping process, the foam is punched, and the foam is squeezed out together with the surface material. To reduce this problem and solve it, the main method is to change the selection of the tool.

The double beveled cutting tool commonly used for die cutting is used. Then, to ensure effective reduction of bevel generation, we use a single-edged blade with straight internal beveling, which can effectively reduce the occurrence of foam slanted edges.

At the same time, for relatively simple EVA foam die-cut parts, we use peeling, edge separation, and jumping methods to reduce factors that affect the formation of slanted edges and avoid slanted edges. For products with slightly more complicated structures, we can use the method of cutting with a cutting blade, without closed cutting lines or multiple overlapping lines, to reduce the extrusion stress during foam stamping and minimize problems with foam angles.

2. Debris generated during EVA foam cutting:

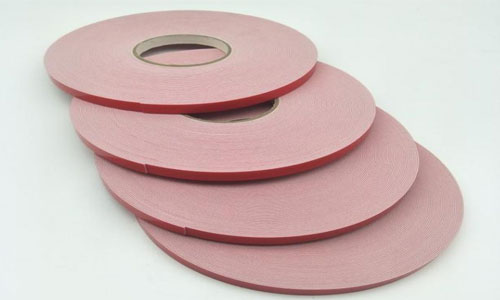

Secondly, regarding the issue of EVA foam debris, the fundamental reason is the nature of the foam itself, as it is low in toughness and has a foam material structure. These factors come into play during the stamping process. With repeated action of the cutting machine, the foam debris particles are prone to form dust and float in the air. There are many methods to solve this problem for die cutting work with cleanliness requirements. Generally, a spray release agent is used. A commonly used method in production lines is to laminate a layer of OPP protective film on the surface of the EVA foam to solve this problem. Of course, this solution may result in some waste of accessories. EVA foam cutting is challenging.

3. Waste material discharge in EVA foam die cutting:

Thirdly, regarding the waste material discharge issue in hole-shaped products, the most fundamental reason lies in the thickness of the foam being too high, coupled with small hole diameters, making it difficult to extract waste material during the waste material discharge process. The traditional approach is to have a set of fixed ejectors attached externally to the die cutting machine mold to discharge the waste material, using spring-loaded pins to pop out the hole-shaped debris and expel the fallen material. However, such waste handling methods are difficult to operate properly and are prone to scratching the foam, resulting in product defects. The method commonly used for circular knives is to extract the knife used for extraction and waste material handling. Today, in response to the emergence of these problems, the editor provides a better working plan, which is an asynchronous working plan.

EVA foam die cutting solution - asynchronous working:

Fourthly, the benefits of the asynchronous operation procedure for EVA foam die cutting lie in the fact that we all know that by using the upper material for asynchronous pulling and synchronous die cutting with the lower material, the purpose of saving material can be achieved. Here, we adopt an asynchronous method to separate the foam from the backing film. This not only saves the foam material, but also in actual operation, the upper material belt will be taken away, and the foam frame will be scraped off. At the same time, it will also be taken away. Additionally, due to the influence of forces, the slanted edges will be greatly improved. Furthermore, through this operating mode, the basic dust problem is effectively resolved.

This is the relevant introduction to the analysis of the processing technology of EVA foam die cutting. Only by addressing the issues in the processing of EVA foam die cutting can the entire die cutting process be completed better, improving the quality and efficiency of die cutting.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat