Die cutting techniques are also employed for digital substrates used in advanced printing technologies. These substrates include materials like vinyl, polyester, polycarbonate, and other synthetic films that are specifically designed for digital printing processes. Here's an overview of die cutting techniques and applications for digital substrates:

1. Vinyl:

- Vinyl is a popular material used for various signage, decals, vehicle wraps, and promotional graphics.

- Die cutting is utilized to create precise shapes and designs in vinyl, allowing for customized graphics and branding.

- The die cutting process ensures clean and accurate cuts, resulting in professional-looking finished products.

2. Polyester:

- Polyester films are commonly used for labels, tags, overlays, and packaging applications.

- Die cutting is employed to cut polyester films into specific shapes and sizes, providing consistent and high-quality finished products.

- The die cutting process allows for intricate designs, precise registration, and efficient production of polyester components.

3. Polycarbonate:

- Polycarbonate films are known for their durability, transparency, and resistance to impact and heat.

- Die cutting is used to shape polycarbonate films into various components, such as membrane switches, control panels, and nameplates.

- The die cutting process ensures accurate cuts and clean edges, maintaining the integrity and functionality of the polycarbonate components.

Die cutting techniques for digital substrates involve using specialized dies and cutting tools that are designed to handle the specific characteristics of these materials, such as their thickness, flexibility, and surface properties. The die cutting process can be performed manually or using automated machinery, depending on the volume and complexity of the production.

In addition to shaping the materials, die cutting can include processes like perforating, scoring, or embossing for added functionality and visual effects. These techniques enhance the versatility and aesthetic appeal of digital substrate components.

Overall, die cutting techniques enable efficient and precise fabrication of digital substrates for advanced printing technologies, allowing for customized designs, high-quality finishes, and durable products.

Here are the topics that we’ll cover in this complete guide Rotary Die Cutting in Industrial Applications Section 2: Categories of Materials in Die Cutting:

2.1 Plastics: Types, Applications, and Die Cutting Considerations

2.2 Non-Metallic Materials: Characteristics and Die Cutting Applications

2.3 Medical Supplies: Die Cutting Challenges and Solutions

2.4 Paper Products: Die Cutting Techniques and Applications

2.5 Neoprene, Film, and Vinyl: Die Cutting Techniques and Applications

2.6 Automotive Components: Die Cutting Solutions for Efficient Production

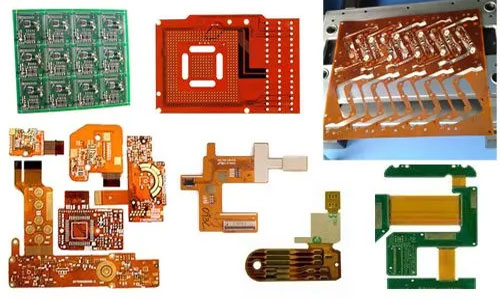

2.7 Electronics: Die Cutting for Precision and Performance

2.8 Non-Wovens: Die Cutting Techniques for Enhanced Efficiency

2.9 Chipboard, Foil, and Corrugated Materials: Die Cutting Considerations

2.10 Fishpaper, Thermal, and Fiberglass: Die Cutting Techniques and Applications

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat