The die-cutting machine is an indispensable and important supporting equipment in printing factories. Paper boxes, cartons, paper bags, paper cans, hanging flags, folding pages, stickers, and other packaging and decoration printing products almost all require die-cutting equipment. Especially with the continuous prosperity of the market economy, the application of die-cutting machines is becoming more and more widespread. The quality and production efficiency of printed products have also placed higher demands on the performance, functionality, and adaptability of die-cutting machines. Therefore, under the trend of continuous development and growth of the printing industry, die-cutting machine production in our country is gradually shifting towards automation, digitization, intelligence, functionality, linkage, high speed, and personalization. This will effectively promote the technological progress of packaging printing in our country.

The die-cutting machine is the main equipment for die-cutting, embossing, embossing, and embossing, and is widely used in the forming and processing processes of paper, cardboard, plastic film, leather products, fabric products, and other products. In daily production, it can be found that a considerable portion of die-cut products actually also include embossing production processes. Therefore, people are used to referring to die-cutting and embossing processes as die-cutting processes. Due to the different structures and characteristics of various products, the die-cutting production methods adopted also differ, and therefore the die-cutting machines also have various structures and forms.

Looking at various die-cutting production equipment on the market, there are various forms and structures, including vertical flat pressure flat structure models, horizontal automatic flat pressure flat structure models; circular pressure flat structure die-cutting machines, circular pressure circular die-cutting machines; die-cutting machines suitable for flat paper, and models for die-cutting reel paper; multifunctional online machines that can both perform electrochemical aluminum hot stamping and die-cutting; models that are linked with corrugated paperboard printing presses for embossing, slotting, and cutting, and die-cutting devices that are operated in conjunction with relief printing, flexographic printing, gravure printing, and offset printing machines, and so on, to meet and satisfy the needs to improve production efficiency and quality of various products. So, what kind of die-cutting machine should be used in a printing factory to maximize production efficiency and product quality? This requires us to first rationally understand the die-cutting process and equipment, understand the structure, performance, and adaptability of different die-cutting machines, grasp the development trends and application trends of die-cutting machines in China in a timely manner, and select suitable die-cutting machines for production based on the production structure and product characteristics of the factory, which is a very important link.

The die-cutting machine manufacturing in China has gone through several decades of development, and the level of production technology and production scale has been greatly improved and expanded. Especially since 2000, domestic die-cutting machine manufacturers have made significant breakthroughs and progress in digesting and absorbing advanced manufacturing technologies from abroad, and the development of equipment has tended toward digitalization, intelligence, diversification, and linkage, and the technical performance and automation level of the equipment has made a qualitative leap. Traditional backward vertical flat pressure flat manual paper-continuing die-cutting machines are gradually being replaced by fully automatic die-cutting machines with high efficiency and quality characteristics, and this trend is becoming more and more significant, especially in some large and medium-sized printing factories in economically developed areas, where the application of horizontal automatic flat pressure flat die-cutting machines is increasing, and it has become the main equipment for die-cutting production in the factory. However, looking at the overall situation of the printing industry, many small and medium-sized printing factories in China mainly rely on orders with a wide variety of products and small production quantities. These factories have limited production scales and benefits. It is still difficult for fully automatic die-cutting equipment to be widely used in the short term. Therefore, although the production efficiency, quality level, and safety factor of the vertical flat pressure flat die-cutting equipment are relatively low, its cheap price, adaptability, and flexibility determine that it still has a certain application value and broad market in the present and for a period of time in the future. Therefore, although various die-cutting machines have their own advantages and disadvantages, maintaining the coexistence of various die-cutting machines in the market can play a complementary role in production, allowing various printing factories to have more flexibility and choices, so that die-cutting equipment in the actual production of the factory can achieve the best balance of efficiency and benefits.

1. Vertical Flat Pressure Flat Die-Cutting Machines. From the current overall situation of the die-cutting machine market application, the market share of vertical flat pressure flat die-cutting equipment is about 65%, making it the main equipment for the printing industry. The current domestically produced vertical flat pressure flat die-cutting machines are mostly of the open and fully open specifications, while the four-open specifications are relatively few. From the perspective of the mechanical structure and characteristics of vertical flat pressure flat die-cutting machines, this type of machine has a simple structure, low precision, poor production performance, unstable product quality, and relatively low production efficiency, with a machine production speed of about 1300 sheets per hour, so it lacks advantages in die-cutting long-line products. However, this machine is easy to operate, quickly switches production, and is flexible. It has a large die-cutting pressure, clear embossing, and can adapt to the thickness of die-cut products. It is especially suitable for die-cutting and embossing small-batch products, and the equipment is relatively low in price, so most printing factories are willing to accept it. Therefore, although this machine uses manual paper-continuing operation, and has a labor-intensive operation, with limited production efficiency and quality, it is useful in the actual circumstances. Given China's actual situation, it is estimated that such machines still have a relatively large application market in China.

2. Rotary Pressure Flat Automatic Die-Cutting Machines. Compared to vertical flat pressure flat die-cutting machines, the rotary pressure flat automatic die-cutting machines with a certain increase in production efficiency and quality are based on the Heidelberg letterpress rotary platform printing machine. The main specifications are of open and four-open types, and the machines can also be equipped with hot stamping devices, with a production speed of about 3500 sheets per hour. Due to the characteristics of the machine's paper feeding and pressurizing mechanism, this machine is suitable for the embossing, embossing, and embossing of copperplate paper, double-coated paper, specialty paper, or whiteboard paper products and can be used for simple die-cutting products. Therefore, this kind of machine is often used in post-printing processing production for cigarette packs, cosmetics, brochure covers, electronics, pharmaceutical packaging, paper bags, and other products. Due to the "surface-to-line" contact state during the machine's pressure working, the pressure is relatively concentrated and uniform, giving the machine a significant quality advantage in terms of embossing, embossing, and convex and concave embossing production. However, due to the machine's structure and adaptability, it is not suitable for die-cutting corrugated boxes or corrugated cartons. Also, the machine does not have a waste clearing device, and the paper receiving device is a chain-type toothed rack that moves semi-finished products in a cyclic manner, so it cannot adapt to products with more complex die-cutting and splicing structures. Due to the characteristics and reasons of the equipment structure, the market share of this type of die-cutting machine is relatively small, estimated to be about 5%.

3. Horizontal Flat Pressure Flat Automatic Die-Cutting Machines. Compared to vertical flat pressure flat die-cutting machines and rotary pressure flat die-cutting machines, horizontal flat pressure flat automatic die-cutting machines have significant advantages. The common models have open and full-open specifications, with normal production speeds of about 6000 sheets per hour, reaching a maximum speed of 9000 sheets per hour, and a die-cutting precision of up to 0.1mm. The equipment performance can basically meet the die-cutting production requirements for fine products. Some models are also equipped with hot stamping devices, further highlighting the functional and competitive advantages of the equipment, making it more suitable for die-cutting and hot stamping of cartons, color boxes, and other fine products. Currently, the market share of domestic automatic die-cutting machines is about 20%, and in the more developed printing areas such as the Yangtze River Delta and the Pearl River Delta, the market share of automatic die-cutting machines is even higher, possibly exceeding 50%. Looking at the development trends of the printing industry, it is expected that the application scope of domestic horizontal flat pressure flat die-cutting machines will continue to expand, with this type of equipment having significant market potential. Furthermore, considering the equipment prices, the prices of domestically produced horizontal flat pressure flat automatic die-cutting machines are only between one-third and one-fourth of the prices of similar foreign products, and with the current over-supply situation for such automatic die-cutting machines in domestic production, it is expected that the prices of such machines will undergo a downward trend. Therefore, in the current and future periods, horizontal flat pressure flat automatic die-cutting machines will be the direction for the development of the printing industry, to achieve technological progress, improve production efficiency, and product quality, gradually replacing traditional and backward vertical flat pressure flat die-cutting machines.

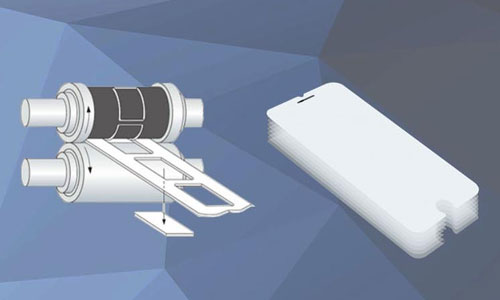

4. Flexographic Printing Machine Die-Cutting Unit. The die-cutting machine unit for online operation with flexographic corrugated board printing machines consists of circular slitting knives, slotting cams, and embossing rollers, and has a simple and rough structure, suitable for cutting, slotting, and embossing corrugated board that is online printed, and can complete the printing and semi-finished die-cutting of the cartons in one step, reducing the intermediate steps in production, shortening the production cycle of carton prints, with high production efficiency, and reduced raw material consumption. However, the die-cutting accuracy of corrugated board is relatively low, and the product quality is also relatively low, generally only applied to the production of medium and low-end cartons. Therefore, this type of machine is more widely used in carton factories, and looking at the overall printing industry, its market share is likely around 5%.

5. Rotary Die-Cutting Machines for Web-fed Printing. The die-cutting machine units for embossing, flexographic, and gravure printing machines for web-fed operations can achieve a production speed of 20,000 sheets per hour, almost equal to the speed of web-fed printing machines, significantly improving die-cutting production efficiency. Because the rotary die-cutting work is in a linear contact state, the working pressure is very small and stable, and the product size is relatively accurate. Also, due to the extremely high wear resistance of the die-cutting rollers, it is beneficial to increase the service life of the die-cutting rollers and the quality of die-cutting products, and reduce the production costs of die-cutting. Therefore, in recent years, with the rapid development of web-fed printing machines, the application of rotary die-cutting technology has also been promoted to a certain extent. However, due to the long processing cycle and the high price of die-cutting rollers, it is only limited to the production of long-run, high-end, and fixed-specification printing products in order to offset the production costs of making die-cutting rollers. Currently, the market share of web-fed rotary die-cutting machine units in China may not exceed 5%, and most of them are used for cigarette pack production.

It can be said that the die-cutting machine is almost a necessary supporting production equipment for every printing factory, and the selection of die-cutting machine for production should mainly be based on the product structure of the factory, choosing models that are suitable for the actual production situation and characteristics of the factory to better improve production efficiency and product quality, and reduce production consumption and costs. Therefore, small printing and packaging factories, carton factories with relatively small production volumes, a wide variety of products, and small production quantities should consider using vertical flat pressure flat die-cutting machines mainly for production. Of course, in the case of a large business volume, a small number of horizontal flat pressure flat automatic die-cutting machines can also be introduced to increase die-cutting production capacity and enhance the competitiveness of the enterprise. For products with a relatively single structure, large production quantities, stable profits, and able to simultaneously perform printing and die-cutting of the packaging products, it may be considered to use fully automatic or multifunctional online die-cutting machine units. Large and medium-sized printing and packaging factories and carton factories with large production scales and relatively fixed business volumes and product varieties should consider purchasing fully automatic die-cutting equipment mainly for production. Carton factories can also consider purchasing flexographic printing machines with die-cutting and embossing units that suit their product characteristics, and should pay attention to the equipment specifications, color groups, functions, and have strong flexibility and adaptability to enhance the market competitiveness of the enterprise.

Looking at the overall production situation of the packaging printing industry, it can be said that die-cutting equipment has a relatively large impact on the production and quality of packaging printing factories, and has been a bottleneck that has constrained the production capacity and market competitiveness of packaging printing factories for many years. Therefore, in order to better adapt to market competition, packaging printing companies must break away from traditional concepts and be brave enough to abandon outdated production practices that do not comply with the development of the times. In accordance with changes in the market and the production characteristics of the factory, they should appropriately develop more advanced die-cutting equipment to reduce the labor intensity of production operators, improve production efficiency and product quality, and reduce production consumption and costs. Only in this way can companies survive and develop more effectively.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat