Bobst die cutters are advanced die cutting solutions that are widely used in various industries. Here are some key features and benefits of Bobst die cutters:

1. Advanced technology: Bobst die cutters are equipped with advanced technologies and features that enhance productivity and efficiency. They incorporate computerized controls, automation, and high-speed capabilities to streamline the die cutting process.

2. Precision cutting: These machines offer precise and accurate cutting, ensuring consistent results. The combination of high-speed operation and advanced registration systems enables tight tolerances and minimal variations in die cutting.

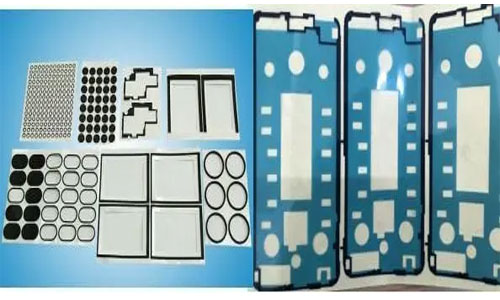

3. Versatility: Bobst die cutters are versatile machines that can handle a wide range of materials, including paper, cardboard, corrugated board, plastic, and thin metal sheets. They can be used for various applications, such as packaging, labeling, displays, and more.

4. Customization: These machines can be tailored to meet specific die cutting requirements. They can accommodate various shapes, sizes, and intricate designs, allowing for customization and flexibility in product manufacturing.

5. Efficiency and productivity: Bobst die cutters are designed to maximize productivity and minimize downtime. They feature quick setup and changeover times, allowing for efficient production runs and reduced waste. They also have high-speed cutting capabilities, enabling faster production rates.

6. Quality control: Bobst die cutters ensure consistent and high-quality die cutting results. They incorporate advanced inspection systems that detect and eliminate defects, ensuring that only accurate and flawless products are produced.

7. Durability and reliability: Bobst die cutters are built to withstand heavy use and demanding production environments. They are constructed with high-quality materials and components, ensuring durability and long-term reliability.

8. Service and support: Bobst provides excellent service and support for their die cutters. They offer training, maintenance, and technical assistance to ensure that the machines operate at optimal performance.

Bobst die cutters are widely used in industries such as packaging, printing, labeling, and automotive. They offer advanced die cutting solutions that enable efficient, precise, and high-quality production. Whether it is creating unique packaging designs, cutting intricate labels, or manufacturing complex automotive components, Bobst die cutters provide the technology and capabilities needed for advanced die cutting applications.

Here are the topics that we’ll cover in this complete guide Rotary Die Cutting in Industrial Applications Section 3: Types of Die Cutters:

3.1 rotary die cutters: Features, Operation, and Applications

3.3 Fabric Die Cutters: Precision Cutting for Textile Industry

3.4 Leather Die Cutters: Versatile Cutting Solutions for Leather Goods

3.5 Cuttlebug Die Cutters: Compact and User-Friendly die cutting machines

3.6 Gemini Die Cutters: High-Quality Die Cutting and Embossing

3.7 Big Shot Die Cutters: Popular Manual Die Cutting Machines

3.8 Circle Die Cutters: Specialized Machines for Circular Cuts

3.9 Eterna Die Cutters: Efficient Die Cutting for Various Materials

3.10 Die Cutters with Embossing Capabilities: Combining Cutting and Embossing

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat