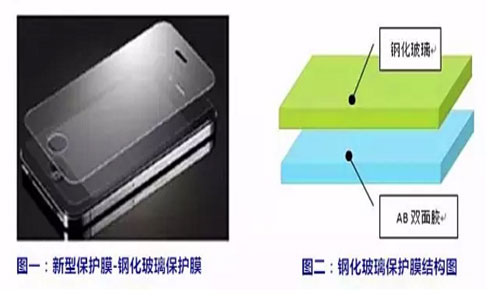

With the smart transformation of mobile phone functions, the mobile phone accessories industry has formed a huge industrial chain in recent years. Mobile phone protective film is one of the typical mobile phone accessories. There are many types of mobile screen protective films on the market, but they usually rely on transparent film materials with static electricity and adhesive attached to the screen. The drawbacks of these products include easy peeling, bubbling, short lifespan, lack of scratch resistance, lack of impact resistance, and difficulty in adhesion and contact. A new type of protective material, such as tempered glass screen protective film, has emerged on the market to address many of these issues.

Tempered glass protective film is easy to use. It only needs to be placed on the mobile phone screen. Users do not need to carefully apply it like a film. It has an automatic exhaust function, so it will not produce unsightly bubbles. Tempered glass film can prevent shattering and scratching, and its toughness is enough to protect the mobile display screen from heavy pressure.

We know that the direct method to fix the tempered glass on the screen is to apply glue, but the glue on the tempered glass cannot be rolled up, making it difficult to achieve mass production. To solve this problem, the current tempered glass protective film is composed of a piece of tempered glass and an "AB double-sided adhesive tape".

Product Structure

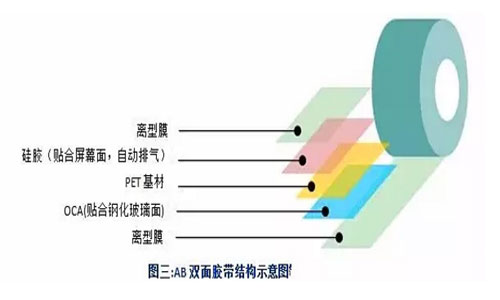

How does tempered glass protective film have adhesive capability? How to achieve self-exhausting bubbles? This will start from the design of our AB double-sided adhesive tape.

The AB double-sided adhesive tape, based on PET, has silicone rubber on one side, and OCA double-sided adhesive can protect the tempered glass. OCA has good adhesion, excellent optical performance, and a certain rough surface filling function, which can adhere to the tempered glass. The organic silicon self-discharging bubbles have excellent performance and adhere to the surface of the mobile screen.

Because the coating types on both sides of the substrate are different and the functions are different, it is called "AB tape".

Factors Affecting the Performance of AB Tape

The exhaust performance of AB tape directly affects the adhesion effect and efficiency of tempered glass. Bubbles or slow exhaust speed are adverse adhesion experiences. What factors will affect the exhaust performance of AB tape?

Silicone selection

Different types of silicone have differences in adsorption, which is the main factor determining the performance of AB tape.

Coating flatness with silicone resin

Poor flatness and uneven thickness are usually the main reasons for bubbles.

Silicone coating thickness

The difference in thickness directly affects the exhaust rate of glass. The thicker the adhesive layer, the faster the exhaust rate.

Substrate stiffness

High substrate stiffness has a positive effect on the smoothness of the adhesive layer coating and has an indirect effect on the exhaust performance.

Advantages of AB Tape

Ultra-thin design, currently available in two thicknesses, 120um and 130um.

Excellent optical performance (total light transmittance > 90%, haze < 1%).

Good adhesion and moisture absorption performance on glass, good machinability. It can completely exhaust within 2 seconds for the iPhone 6 Plus screen (5.5 inches) to achieve a bubble-free and watermark-free effect.

No residual glue or pollution after tearing.

By self-made core materials and mass production, we can greatly reduce costs and bring substantial benefits to customers.

A new solution SLT-2000S has been launched for color shell tempered glass.

This is the end of today's introduction to the structure and influencing factors of AB double-sided adhesive tape for die-cutting materials. Due to the wide application of this tape in our daily lives, there are certain requirements for die-cutting accuracy. Fumart flatbed die-cutting machine is an experienced practitioner in the die-cutting industry, and can adjust relevant accuracy according to customer requirements, making it your best choice for material processing.

Contact: Pamela

Phone: +86 189 6365 3253

E-mail: info@industryprocess.com

Whatsapp:+86 189 6365 3253

Add: Yajing Industrial Park, No. 59 Shuangjing Street, Weiting Town, Suzhou Industrial Park

We chat